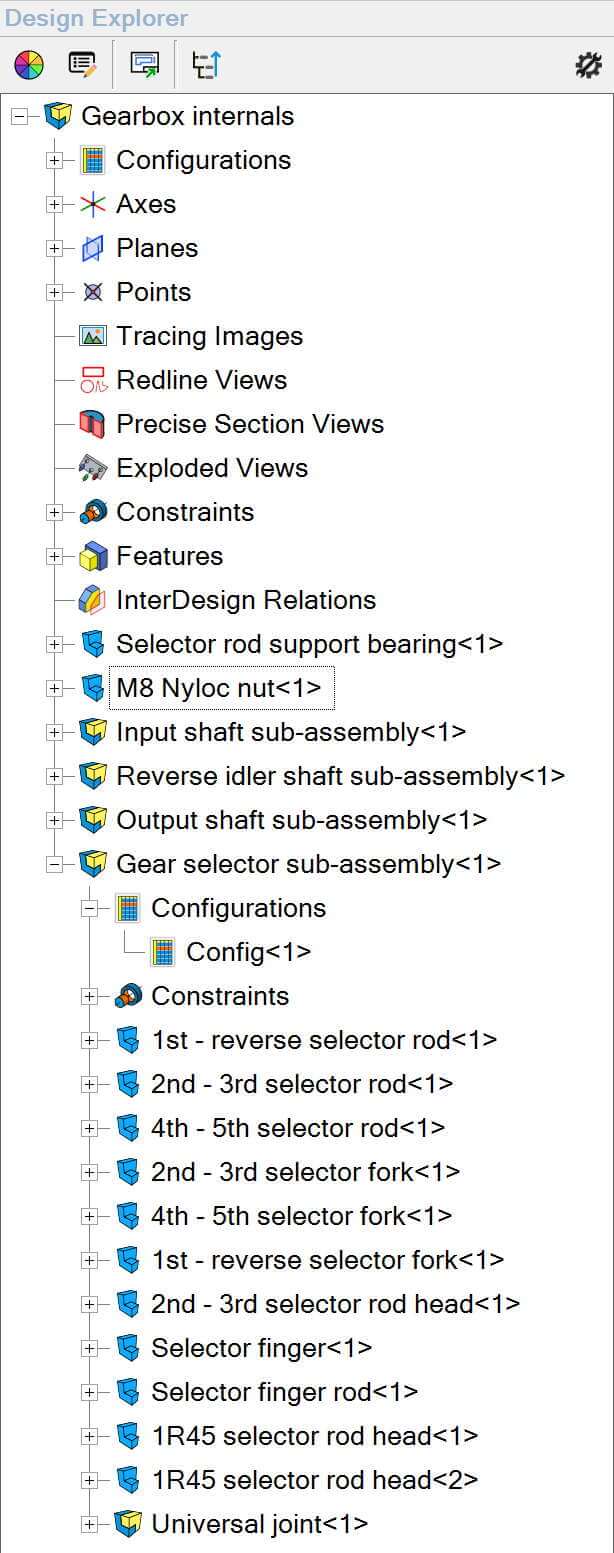

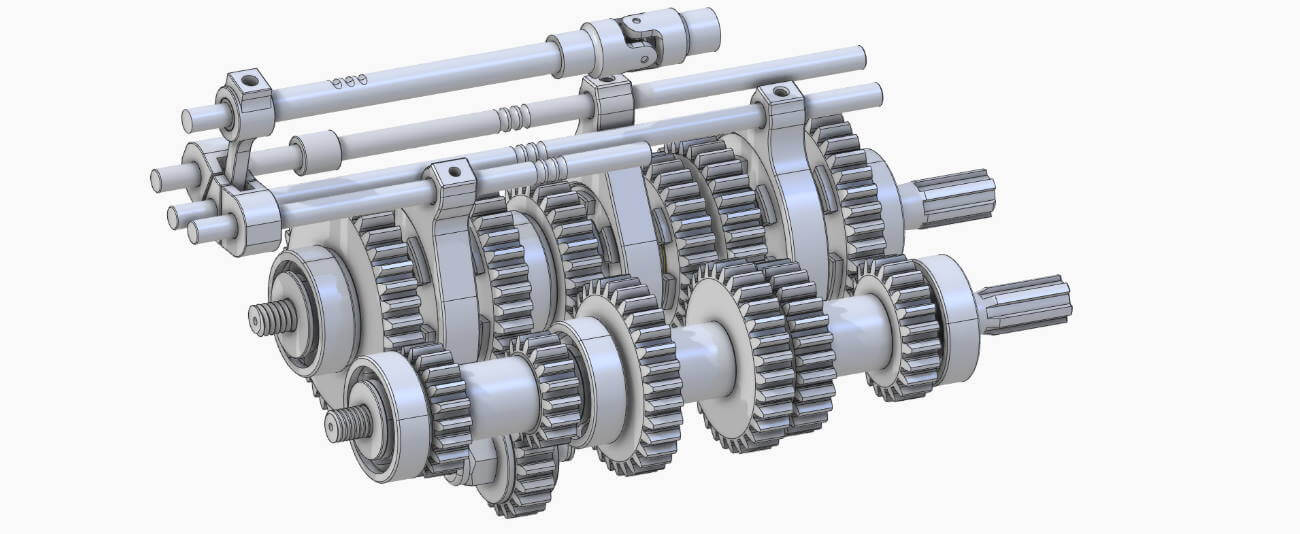

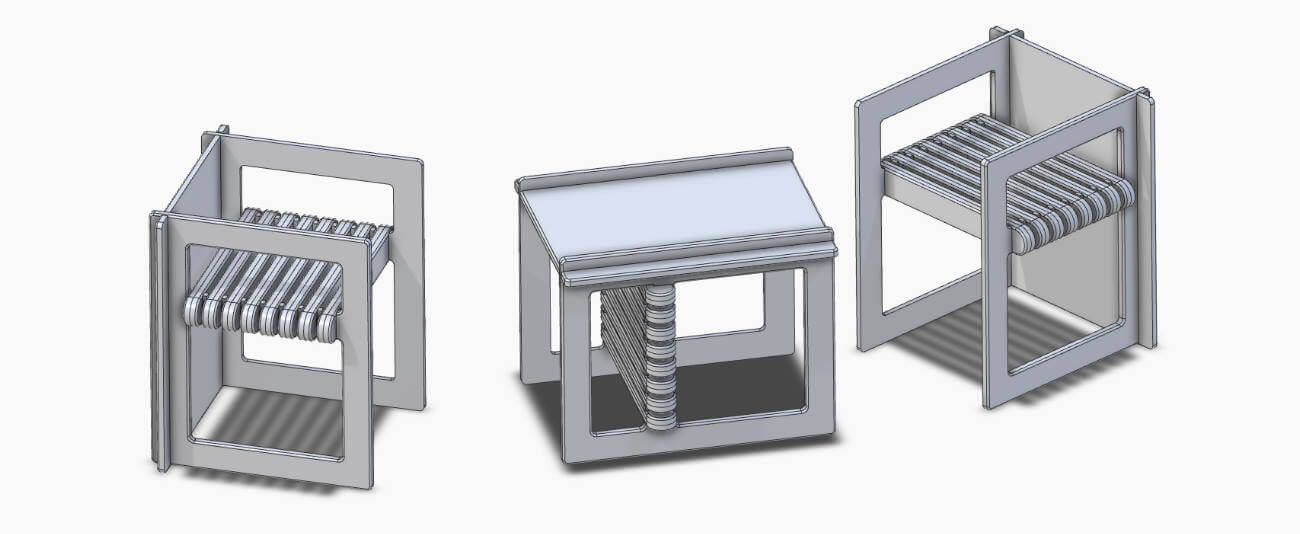

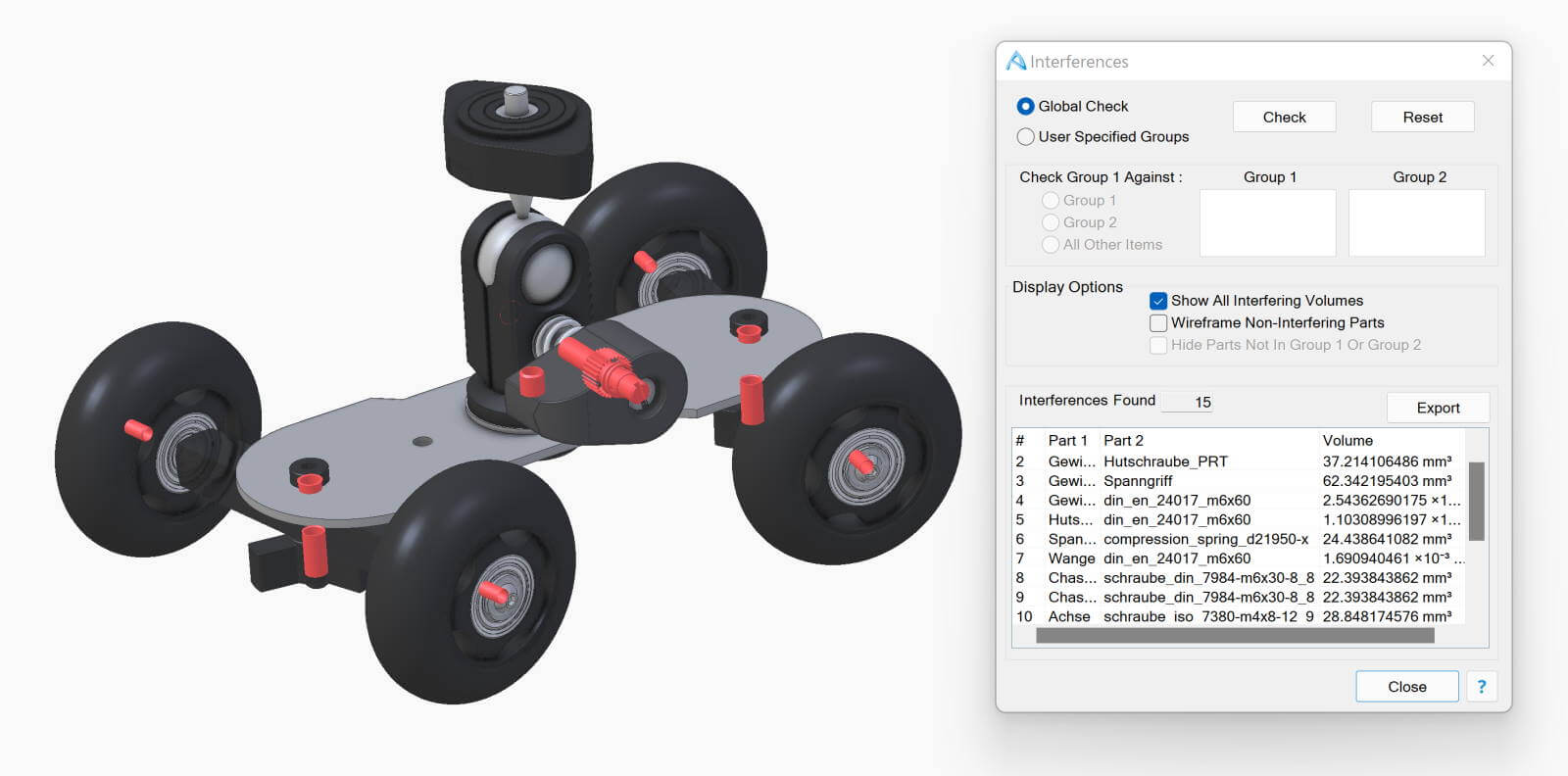

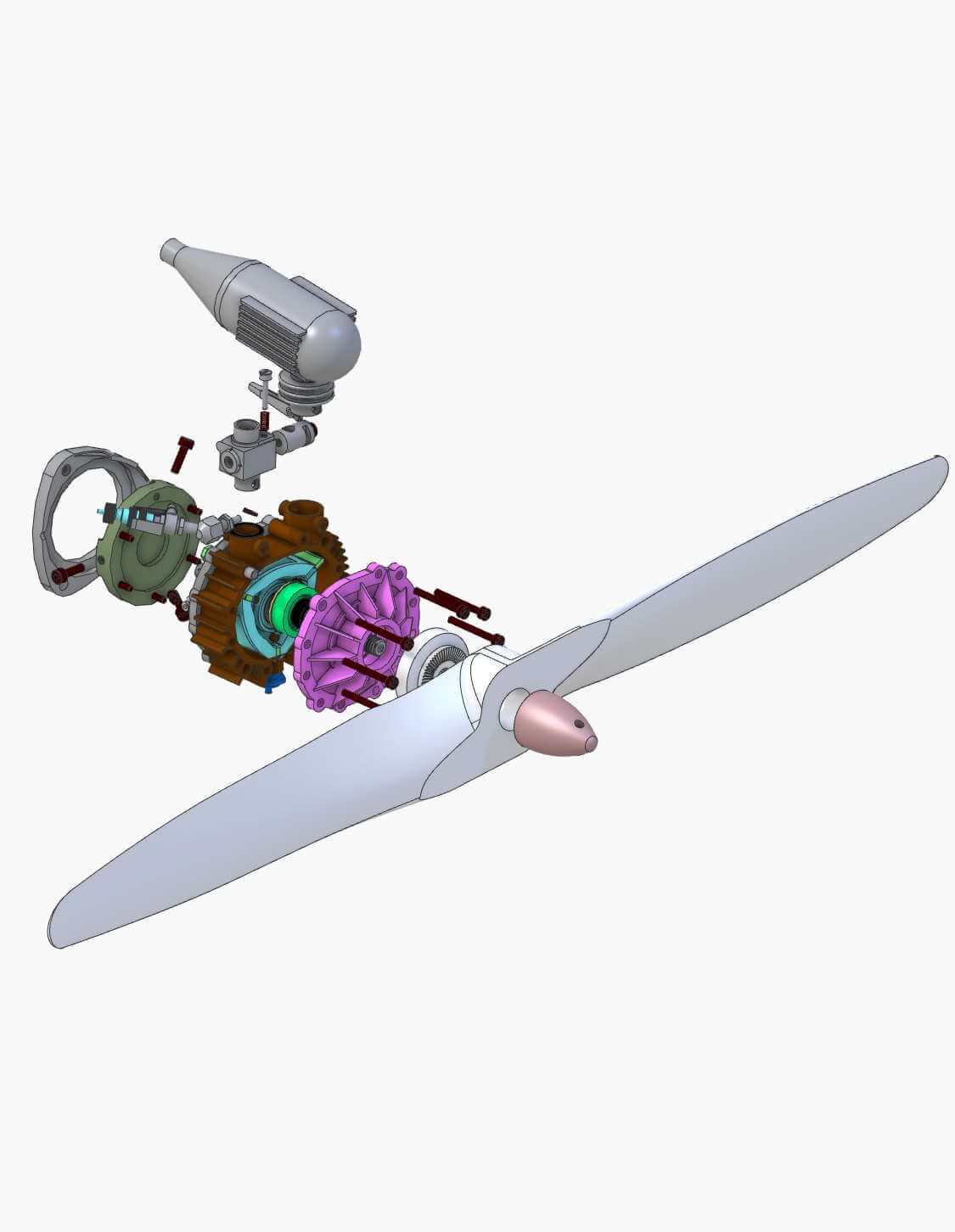

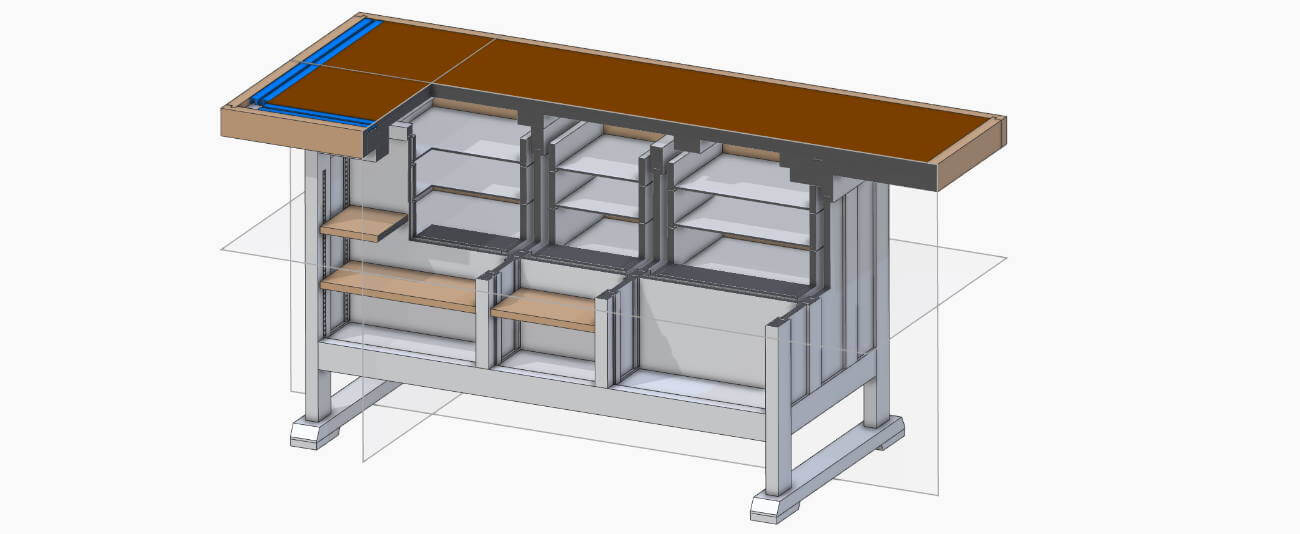

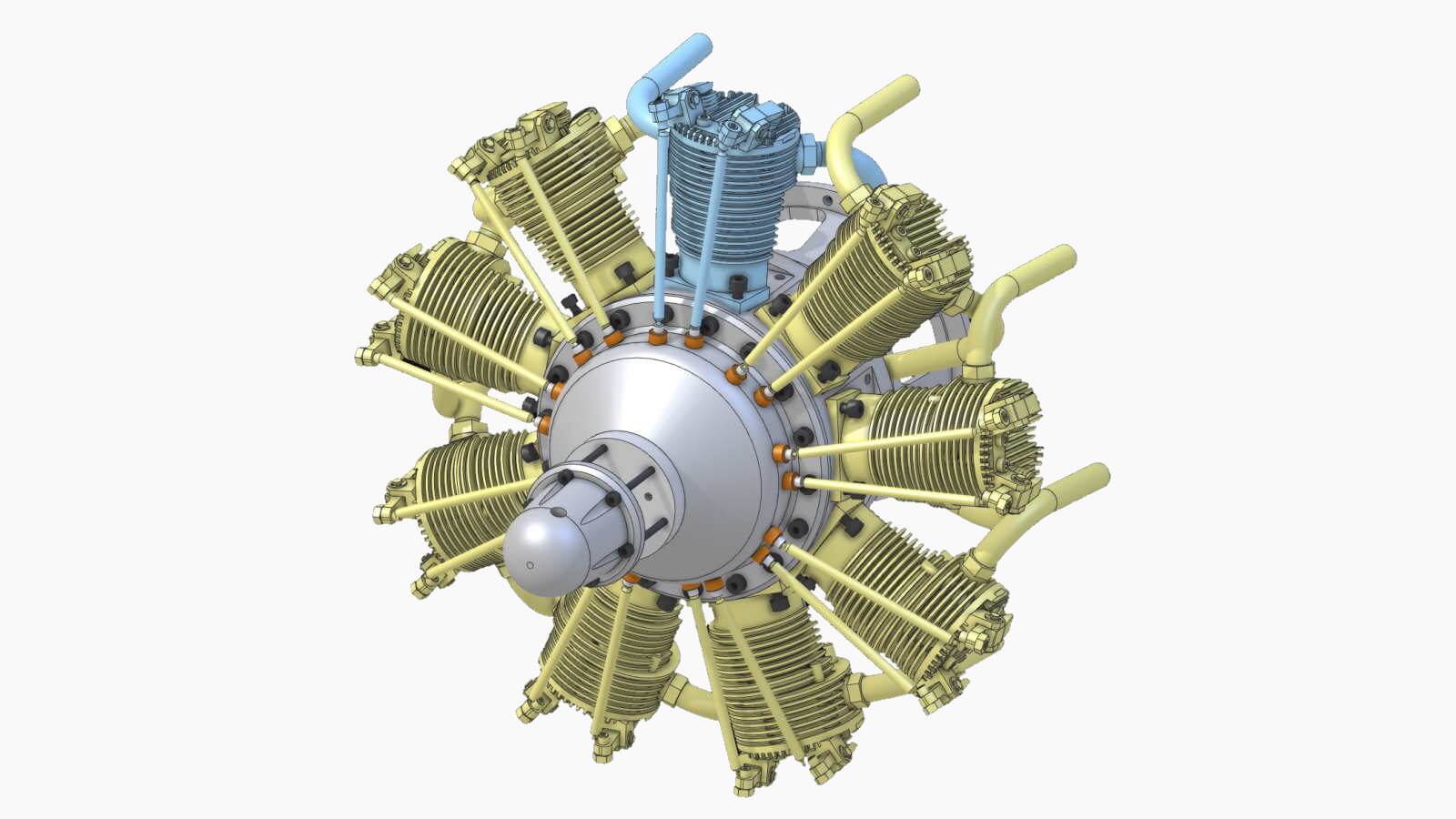

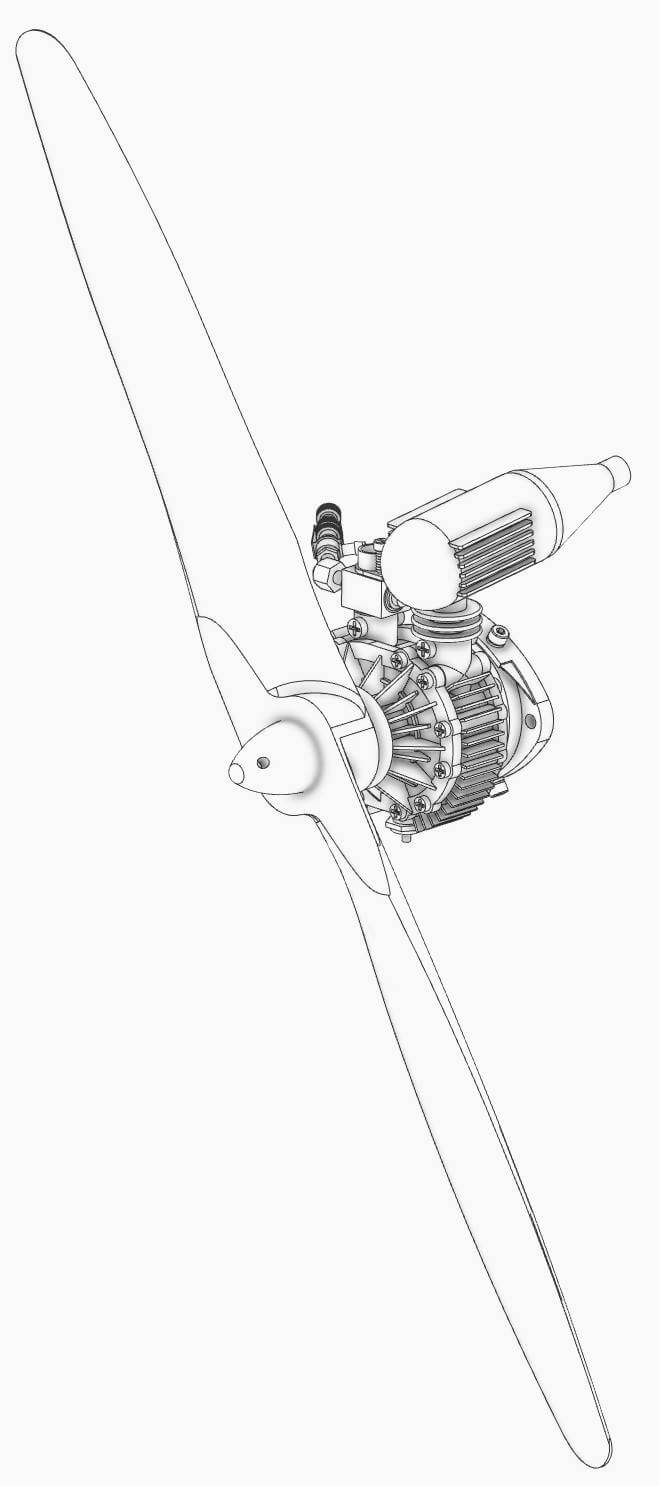

Bottom-up design refers to the process of creating individual components and then bringing them together into an assembly, using constraints to define positional relationships.

This method is ideal when modeling parts that are unlikely to change as the design evolves, such as fasteners, motors, and other off-the-shelf components. Editing parts designed in this way requires manual changes to the part's sketches and features.