OzBrand

Member

Hi All,

It's been a long while since I've been on here (few years maybe). Haven't done too many projects lately.

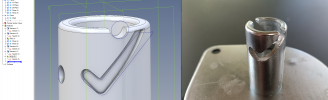

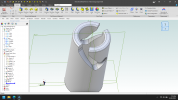

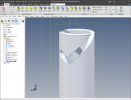

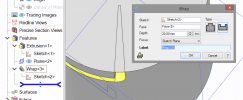

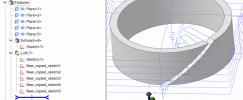

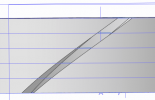

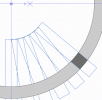

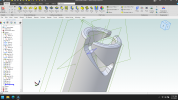

I'm a bit hung up on figuring the best way to handle this task. The pic attached is a shaft from a battery isolator which accepts a lever with two guide studs. I need to recreate the slot for the guide studs. The slot which is mirrored across the shaft's centreline axis is perpendicular to the outer cylindrical surface.

This particular example appears to be punched but I have another version which appears to be milled.

So my question is, how would one go about tackling this? I have placed a starting and finishing point on the attached AD-PRT file.

Cheers, Mike B.

It's been a long while since I've been on here (few years maybe). Haven't done too many projects lately.

I'm a bit hung up on figuring the best way to handle this task. The pic attached is a shaft from a battery isolator which accepts a lever with two guide studs. I need to recreate the slot for the guide studs. The slot which is mirrored across the shaft's centreline axis is perpendicular to the outer cylindrical surface.

This particular example appears to be punched but I have another version which appears to be milled.

So my question is, how would one go about tackling this? I have placed a starting and finishing point on the attached AD-PRT file.

Cheers, Mike B.