You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cut normal to curve

- Thread starter laverne3ca

- Start date

laverne3ca

Senior Member

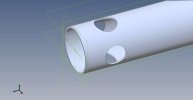

I think I got it though there may be a better way, I extended the line from the center to the inside wall to the plane where the ellipse is drawn to dimension the ellipse, then made a .002 x .527 ellipse on the centerline and did a cut loft through. Not sure if that's the best way but it seems to have worked or is at least very close. Any suggestions to make it better are appreciated.I'm trying to model a tube with a laser cut profile through the side. The tube OD is 1.125 with an .035 wall and I need a .527 hole through. To get the .527 dimension the laser would need to cut an ellipse .527 x .589, how can that be done.

As I couldn't see what the cut loft looked like, I made a loft using the same ellipse and the results are close but it doesn't look right, all the surfaces don't appear to be normal to the tube OD, the loft still needs to be changed to get more accurate results.

Attachments

Last edited:

Ken226

Alibre Super User

My first thought was to use the wrap tool. I'm pretty sure V26 has it:

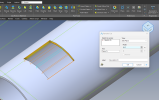

If you don't have that tool available, then maybe a midplane revolve cut, and some fillets. With the midplane revolve, 53.7 degrees got me an arc length of .527 on the outside of the tube. I had to play around with the fillets though, as it wanted to throw some errors:

If you don't have that tool available, then maybe a midplane revolve cut, and some fillets. With the midplane revolve, 53.7 degrees got me an arc length of .527 on the outside of the tube. I had to play around with the fillets though, as it wanted to throw some errors:

NateLiquidGravity

Alibre Super User

I would make the tube in sheet metal by doing a circle to circle lofted flange then using sheet metal cuts. The edges are made normal to the surface that way.

help.alibre.com

help.alibre.com

If you enable "Show Part Modeling Tab in Sheet Metal" in the system options display tab then at the end you can use regular tools to cut off the sheet metal tab and fill in the gap.

Articles

If you enable "Show Part Modeling Tab in Sheet Metal" in the system options display tab then at the end you can use regular tools to cut off the sheet metal tab and fill in the gap.

laverne3ca

Senior Member

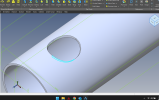

the wrap works well, I just needed to calculate the ellipse dimensions first and the cut is normal to the surface, just what I needed.My first thought was to use the wrap tool. I'm pretty sure V26 has it:

View attachment 41261

If you don't have that tool available, then maybe a midplane revolve cut, and some fillets. With the midplane revolve, 53.7 degrees got me an arc length of .527 on the outside of the tube. I had to play around with the fillets though, as it wanted to throw some errors:

I would either model this via Nate's suggestion or by using thicken surface. See the attached part file.

Basically you extrude cut a round hole and then use delete face to remove all but the face on the ID of the pipe. Then thicken the surface outwards, use the equation editor for the thickness so the OD will update if you were to change anything in sketch 1. I used Topology pattern for multiple holes. You could pattern before using delete face but that is more faces you need to select.

Make sure you have surface visibility turned on View Tab > Reference Display > Toggle surfaces.

Basically you extrude cut a round hole and then use delete face to remove all but the face on the ID of the pipe. Then thicken the surface outwards, use the equation editor for the thickness so the OD will update if you were to change anything in sketch 1. I used Topology pattern for multiple holes. You could pattern before using delete face but that is more faces you need to select.

Make sure you have surface visibility turned on View Tab > Reference Display > Toggle surfaces.

Attachments

HaroldL

Alibre Super User

It's amazing the different ways to use the surface commands.I would either model this via Nate's suggestion or by using thicken surface.

and make sure to Hide the surface when done so the hole pattern is viewable.Make sure you have surface visibility turned on View Tab > Reference Display > Toggle surfaces.