Hello! I am trying to constrain a pulley to a spoked wheel in an assembly. The problem is that the spokes are not in plane--they are conical/dished. I need the inside edge of the pulley to rest on the outside of each spoke.

When the spokes are in plane, I accomplish this with a tangent constraint on the spokes or by creating a plane tangent to the spokes and aligning to that. When the spokes are angled/dished as shown, it is not as simple and I have not found a good solution.

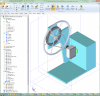

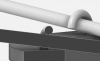

The screenshot shows the objects that need to be constrained.

Thanks!

Eron

When the spokes are in plane, I accomplish this with a tangent constraint on the spokes or by creating a plane tangent to the spokes and aligning to that. When the spokes are angled/dished as shown, it is not as simple and I have not found a good solution.

The screenshot shows the objects that need to be constrained.

Thanks!

Eron