MaskOfSanity

Member

Hello,

i am currently developing a just for fun External Forms Application to do some Stuff with Alibre Design via API.

(creating default Shapes for L, T, S, U-Profile, Involute Gears and with the new Release i tried a CAM based on 3D-Sketches)

This works really nice if you do it from the application side. For improvement of UX i thought it would be easy to use Alibre Design direct to Pick Items but this doesn't work like expected.

Has anyone some advice, hints or tips?

More detailed explanation:

I used the Example from "SelectionAddOnSample" and transfered it to C#. Only for the first 2 cases, Vertices and Edges.

Then i do a auto selection of some edges.

After that i used

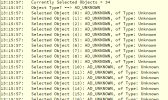

As Result i get:

What can i do to readback selected Elements?

Selection of testCollector works, but i can't do anything with the Data inside IObjectCollector.

Need Help.

Greetings.

i am currently developing a just for fun External Forms Application to do some Stuff with Alibre Design via API.

(creating default Shapes for L, T, S, U-Profile, Involute Gears and with the new Release i tried a CAM based on 3D-Sketches)

This works really nice if you do it from the application side. For improvement of UX i thought it would be easy to use Alibre Design direct to Pick Items but this doesn't work like expected.

Has anyone some advice, hints or tips?

More detailed explanation:

I used the Example from "SelectionAddOnSample" and transfered it to C#. Only for the first 2 cases, Vertices and Edges.

Then i do a auto selection of some edges.

After that i used

C#:

void exampleMethod()

{

SelectionHelper selectionHelper = new SelectionHelper(); // This is the example implementation from SelectionAddOnSample --> CSelectObjectCommand::OnSelect(...)

selectionHelper.OnSelect(session, 1);

IObjectCollector collector = session.SelectedObjects; // From the active part session get the selected objects (i think this could be a picker)

if (collector != null)

{

logbuch.print("Currently Selected Objects = " + collector.Count.ToString());

logbuch.print("Object Type? ==> " + collector.ObjectType.ToString());

for (int i = 0; i < collector.Count; i++)

{

string typeName = "Unknown";

object test = null;

try

{

IObjectCollector testCollector = session.Root.NewObjectCollector(); // Additional Collector to get the First Edge Element of the whole selection

if (i == 0)

{

testCollector.Add(collector.Item(i));

session.Select(testCollector);

}

test = collector.Item(i) as IADEdge;

if (collector.Item(i) is IADEdge edge)

{

typeName = "IADEdge";

}

}

catch (Exception ex)

{

logbuch.print("Error: " + ex.Message);

}

logbuch.print("Selected Object (" + i.ToString() + "): " + (collector.ObjectType.ToString()) + ", of Type: " + typeName);

}

}

}As Result i get:

What can i do to readback selected Elements?

Selection of testCollector works, but i can't do anything with the Data inside IObjectCollector.

Need Help.

Greetings.