RocketNut

Alibre Super User

Part 1

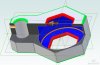

I was wonder if someone can help with a drawing of a part. The first attached screen shows the part diametric. When tried to make a drawing of said part, the drawing is a real mess (as shown in the attached screenshot). I do not know how to spec out the hexagon opening. Also, I do not know how to assign the round overs (the blue text).

View attachment 29448

I was wonder if someone can help with a drawing of a part. The first attached screen shows the part diametric. When tried to make a drawing of said part, the drawing is a real mess (as shown in the attached screenshot). I do not know how to spec out the hexagon opening. Also, I do not know how to assign the round overs (the blue text).

View attachment 29448