bolsover

Senior Member

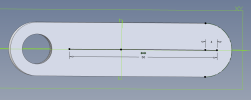

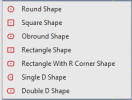

While working up a design for a very simple slotted arm, I found real difficulty with use of Standard Features and particularly with the Obround shape. I'm wondering how others use these features and overcome the problems I found.

For the attached Arm.AD_PRT, I used the Obround shape for the main profile and simply anchored this to the origin to create a fully defined sketch. I would not normally anchor a line/arc like this but would instead use dimensions to define the location.

For the threaded hole, I used project to sketch on the main body right arc to obtain the centre point of the hole. - No problem.

For the slotted hole, I had expected to be able to use a similar project to sketch technique to constrain the centre of the right slot arc to the centre of the main body left arc. However this appears to be impossible; the only option being to manually calculate the location of the slot centre point.

How to others overcome this issue - or do you simply not use Standard Features in this way?

For the attached Arm.AD_PRT, I used the Obround shape for the main profile and simply anchored this to the origin to create a fully defined sketch. I would not normally anchor a line/arc like this but would instead use dimensions to define the location.

For the threaded hole, I used project to sketch on the main body right arc to obtain the centre point of the hole. - No problem.

For the slotted hole, I had expected to be able to use a similar project to sketch technique to constrain the centre of the right slot arc to the centre of the main body left arc. However this appears to be impossible; the only option being to manually calculate the location of the slot centre point.

How to others overcome this issue - or do you simply not use Standard Features in this way?