You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sheetmetal, how to close a large gap

- Thread starter Kunstmaan

- Start date

NateLiquidGravity

Alibre Super User

I'd edit the sketch of the flange and draw it in there.

Kunstmaan

Alibre Super User

TWont open, is missing a partI had to take a couple of attempts, but 'convert to sheet metal' seems to do an OK job.

I suppressed your Shell operation - that isn't needed.

Kunstmaan

Alibre Super User

That doenst work, I cant edit the single flangeI'd edit the sketch of the flange and draw it in there.

Attachments

oldfox

Alibre Super User

That doenst work, I cant edit the single flange

Mareike, If the dogbone isn't at the bottom of the feature list and you can't move it, then do a "save as" and then try again.

I've wasted a lot of time trying to do something that just won't work and then remember to try saving. That usually releases

whatever is locked up and I continue on with my work. This didn't used to happen, just in this latest build. (maybe the

previous one also)

idslk

Alibre Super User

HaroldL

Alibre Super User

Been there, done that. Close Corners needs both edges to be straight. Otherwise It won't close and trim the flanges. Bummer.

Mareike, This would be a good part to send to Alibre so they can test it with "Convert to Sheet Metal" and "Closed Corners". Maybe some sheet metal enhancements could come of it.

Mareike, This would be a good part to send to Alibre so they can test it with "Convert to Sheet Metal" and "Closed Corners". Maybe some sheet metal enhancements could come of it.

Last edited:

oldfox

Alibre Super User

do you get a different result?

Modified Sketch<2> by changing the side offsets to 0.6mm in place of 0.55mm. No errors

Attachments

HaroldL

Alibre Super User

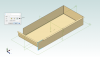

oldfox, by changing the width of the large bend it introduced an issue where the side bends are now extending the full length of the flange instead of stopping at the large bend. It makes it difficult to fillet the corners without adding an Extrude Cut.

A better solution would be to add the side flanges individually and edit the sketch for each of them by extending them 60 mm and applying a fillet of 60 mm to match the inside face of the large bend.

Hope you don't mind but I took the liberty of editing your model to make the changes.

A better solution would be to add the side flanges individually and edit the sketch for each of them by extending them 60 mm and applying a fillet of 60 mm to match the inside face of the large bend.

Hope you don't mind but I took the liberty of editing your model to make the changes.

Attachments

oldfox

Alibre Super User

Hope you don't mind but I took the liberty of editing your model to make the changes.

NP - I don't do sheet metal so edit away.

I just looked at the model as a 3D and saw that the sides infringed on the bend causing the interference and just used the first solution

that came to mind.

One of these days I will learn sheet metal just to end all of this boring pandemonium. (correct spelling)

jhiker

Alibre Super User

Kunstmaan

Alibre Super User

It works. I had to adjust only one dimensionHello Mareike,

will this work for you?

View attachment 31117

(Please check dimension before use...)

Regards

Stefan

Thanks

jhiker

Alibre Super User

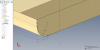

Is there something funny going on here?

View attachment 31146

There is a work around. the close corner tends to do that on large radius's.

see file attached.