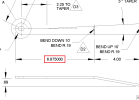

So this change seems to be a side effect of the DoF callout.

I didn't see it because I don't normally use DoF callout. It seems that the way DoF callout interacts with Precision is different to the standard Dimension tool.

At least I understand what is happening now.- I'll log this for investigation.

I didn't see it because I don't normally use DoF callout. It seems that the way DoF callout interacts with Precision is different to the standard Dimension tool.

At least I understand what is happening now.- I'll log this for investigation.