Hello everyone,

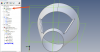

I would need advice on how to make bent flanges on the enclosed part.

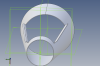

The bends should look like the attached picture. The requirement is that the sheet is round and not bent into pieces.

While searching, I came across the fact that the SW is not able to make bends on a curved surface.

Unfortunately, I do similar things quite often and this is quite limiting.

Any ideas or tricks?

Thank you all for any advice, ideas or tricks.

I would need advice on how to make bent flanges on the enclosed part.

The bends should look like the attached picture. The requirement is that the sheet is round and not bent into pieces.

While searching, I came across the fact that the SW is not able to make bends on a curved surface.

Unfortunately, I do similar things quite often and this is quite limiting.

Any ideas or tricks?

Thank you all for any advice, ideas or tricks.