bengal

Member

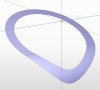

So glad Alibre is back, haven't messed with it since about 2008 when I modeled a pressure vessel on the demo. Curious if it can flatten this surface somehow, see attached image. This is a surface of a nozzle reinforcement pad which goes on a tank head in the knuckle area which makes it tricky.

Couldn't flatten it as a sheet metal part in Bricscad V16 due to the curves being non-planar and the surface tools are limited so that's a dead end. Could try the demo again but thought maybe some Alibre gurus can give some insight on this, thanks!

Couldn't flatten it as a sheet metal part in Bricscad V16 due to the curves being non-planar and the surface tools are limited so that's a dead end. Could try the demo again but thought maybe some Alibre gurus can give some insight on this, thanks!