JST

Alibre Super User

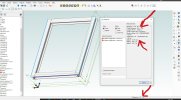

I run into silly and unprofessional dimensions that don't go away.

Things like 3' 12".

To any half intelligent semi-human, that is simply 4'. But Alibre insists that it is 3' 12" (which it technically is, of course, it is a sort of "semantics" issue). I have several of these in a drawing right now, in the materials list, and I can't get them to go away. I do not want to edit them, as then they will not be linked to the actual part anymore, and I will have to do any updates manually.

Naturally, in this actual part drawing, they are fine, 4'. It is just the materials list that is fouled up, reason for the difference is unknown. However they do show up in part dimensions also sometimes. I have ca dimension on many parts labeled as "length" and the BOM set up to take that named field and put it in a column of the BOM for each such part.

EDIT: I take it back, I also found an 11' 12" dimension in a part drawing Oddly, THAT one is listed as 12' in the BOM. Go figure.

Not only is this crazy dimension silly and unprofessional, but it is also potentially misleading. The person using the print may read it as 3' and some number of inches, and get it wrong. (Of course they should be careful. But Alibre should not make that dimension to begin with.

I assume this is a byproduct of rounding. If the real dimension was 3' 11 63/64", and you limit the resolution to 1/32" or 1/16" (which are considered "precision" by ironworkers), then the rounding up to the next inch could come out as 3' 12". I see that. I don't like it, but I understand the issue.

Checking that, I find that yes, it IS apparently rounding, as the part comes out as 11' 11 255/256", if I set the resolution to 256ths of an inch (an insane fractional value that nobody in the world uses, BTW). So Alibre rounded it up, came out to an even value, and used that without checking if it needed to increment the major units instead.

But it is so silly that it ought to just have a filter on it to put the rounded figure up as the even number of "units" (feet in this case) that the as-rounded number really is. That would be much better, more readable, less confusing, and far more "professional".

I have no idea if similar things occur in the Metric calculations. I have never seen it, but with ironwork in USA, I don't see much metric at the moment.

Things like 3' 12".

To any half intelligent semi-human, that is simply 4'. But Alibre insists that it is 3' 12" (which it technically is, of course, it is a sort of "semantics" issue). I have several of these in a drawing right now, in the materials list, and I can't get them to go away. I do not want to edit them, as then they will not be linked to the actual part anymore, and I will have to do any updates manually.

Naturally, in this actual part drawing, they are fine, 4'. It is just the materials list that is fouled up, reason for the difference is unknown. However they do show up in part dimensions also sometimes. I have ca dimension on many parts labeled as "length" and the BOM set up to take that named field and put it in a column of the BOM for each such part.

EDIT: I take it back, I also found an 11' 12" dimension in a part drawing Oddly, THAT one is listed as 12' in the BOM. Go figure.

Not only is this crazy dimension silly and unprofessional, but it is also potentially misleading. The person using the print may read it as 3' and some number of inches, and get it wrong. (Of course they should be careful. But Alibre should not make that dimension to begin with.

I assume this is a byproduct of rounding. If the real dimension was 3' 11 63/64", and you limit the resolution to 1/32" or 1/16" (which are considered "precision" by ironworkers), then the rounding up to the next inch could come out as 3' 12". I see that. I don't like it, but I understand the issue.

Checking that, I find that yes, it IS apparently rounding, as the part comes out as 11' 11 255/256", if I set the resolution to 256ths of an inch (an insane fractional value that nobody in the world uses, BTW). So Alibre rounded it up, came out to an even value, and used that without checking if it needed to increment the major units instead.

But it is so silly that it ought to just have a filter on it to put the rounded figure up as the even number of "units" (feet in this case) that the as-rounded number really is. That would be much better, more readable, less confusing, and far more "professional".

I have no idea if similar things occur in the Metric calculations. I have never seen it, but with ironwork in USA, I don't see much metric at the moment.

Last edited: