Hi and thanks for the great help given in the past, I hope you can help me again.

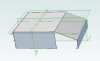

I want to make a part using the sheet metal tools. I have attached the solid version that I want to replicate. and my attempt at the sheet part. However I'm stuck as you will see on how to fill in a missing section.

Any pointers appreciated

Many thanks

Tim

I want to make a part using the sheet metal tools. I have attached the solid version that I want to replicate. and my attempt at the sheet part. However I'm stuck as you will see on how to fill in a missing section.

Any pointers appreciated

Many thanks

Tim