I would have designated the parameters using accepted industry symbols, rather than values, on the Alibre example drawing. Then placed a small lookup table next to it which provided the associated values. Those changes, along with the drawing from efunda.com would have provided sufficient information to correctly follow the example to its conclusion. I'm certain that whoever created the example did so in Alibre and just copied the sketch, complete with dimensions, to the Help document.

Perhaps an Alibre feature that provides the option of creating a parameter lookup table which is associated with symbols used in place of specific dimensions on a drawing would be a desirable feature. I will suggest that to the Alibre folks.

An all inclusive thread table would not be needed, just one containing the information relating to the specified example thread would be sufficient.

I am already aware of the existence of the Cosmetic Threats function. I appreciate that as an option, however the need for details on any particular drawing can only be determined by the designer, knowing the intended audience.

This particular part is the center piece of a mechanical design and being able to see the threads on it greatly enhances the ability of a viewer, other than the designer (me), to understand the function of the product with a minimum of explanation. Were I drawing something like an entire engine block assembly, I would provide Cosmetic Threads on the various components used along with separate drawings showing examples of the True Threads on each threaded part, other than stock bolts and nuts. The primary goal of any drawing is to clearly illustrate what is expected to those who do not already know. It is neither to glorify the technical expertise of the designer nor perpetuate his/her employment, nor, for most of us, is it purely entertainment. Many years ago, I studied engineering, including mechanical drawing, at Penn State (Nobody had CAD then, not even NASA!). There I learned that a drawing which is logical, straight forward and relatively easy to comprehend by those who may not be engineers is often paramount to the success of any project. Anything less is deficient. If it takes a few extra seconds, or even minutes, to do a redraw, so be it. (Try having to take a week to do the same job by hand.) After all, Alibre is not a video game. Instant gratification is not the most important thing.

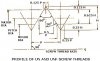

Sorry about the bad drawing link. Here is it again, copied right from my browser:

http://www.efunda.com/designstandards/s ... thread.gif

I will go ahead and report this to Alibre Support.

TG