Hi Everyone,

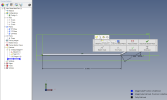

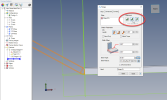

I'm using Alibre Design Expert V23, and trying to create angled bends at the edges of a sheet metal part. If I use the "Flange" tool and roll the flange to 90 degrees (inside alignment) it works great, and keeps the edge-to-edge dimension of the original part. The issue is that I need to have the the flange at a 30-45 degree angle, and when I do that, the flange "creeps" outward, increasing the edge-to-edge dimension of the original part. Is there a way I can create a bend like this while preserving the edge-to-edge dimension of the original part?

Any assistance is appreciated...

I'm using Alibre Design Expert V23, and trying to create angled bends at the edges of a sheet metal part. If I use the "Flange" tool and roll the flange to 90 degrees (inside alignment) it works great, and keeps the edge-to-edge dimension of the original part. The issue is that I need to have the the flange at a 30-45 degree angle, and when I do that, the flange "creeps" outward, increasing the edge-to-edge dimension of the original part. Is there a way I can create a bend like this while preserving the edge-to-edge dimension of the original part?

Any assistance is appreciated...