Hiya folks,

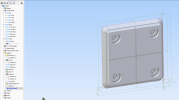

I've been trying to recreate the gridfinity bin geometry to get a bit more familiar with Alibre. Creating a single base is simple enough but I have a few things I've been struggling with.

1) For the overall base profile, I create a profile and sweep cut that around an extruded block. I had to create a path for a single side and then feature pattern that around the remaining sides. Is there a way to do this with a single path/no pattern?

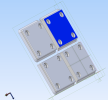

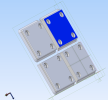

2) One of the aspects of the gridfinity bins is that you can tile the bases to achieve larger bin sizes. When I try to linear pattern I get cut off portions due to it repeating my sweep cuts. Is there a way around this problem?

I've tried to use a linear topology pattern instead but I get the following (PTRN_BAD_BUMP) error:

Any insights would be much appreciated! Thank you.

I've been trying to recreate the gridfinity bin geometry to get a bit more familiar with Alibre. Creating a single base is simple enough but I have a few things I've been struggling with.

1) For the overall base profile, I create a profile and sweep cut that around an extruded block. I had to create a path for a single side and then feature pattern that around the remaining sides. Is there a way to do this with a single path/no pattern?

2) One of the aspects of the gridfinity bins is that you can tile the bases to achieve larger bin sizes. When I try to linear pattern I get cut off portions due to it repeating my sweep cuts. Is there a way around this problem?

I've tried to use a linear topology pattern instead but I get the following (PTRN_BAD_BUMP) error:

Any insights would be much appreciated! Thank you.