RocketNut

Alibre Super User

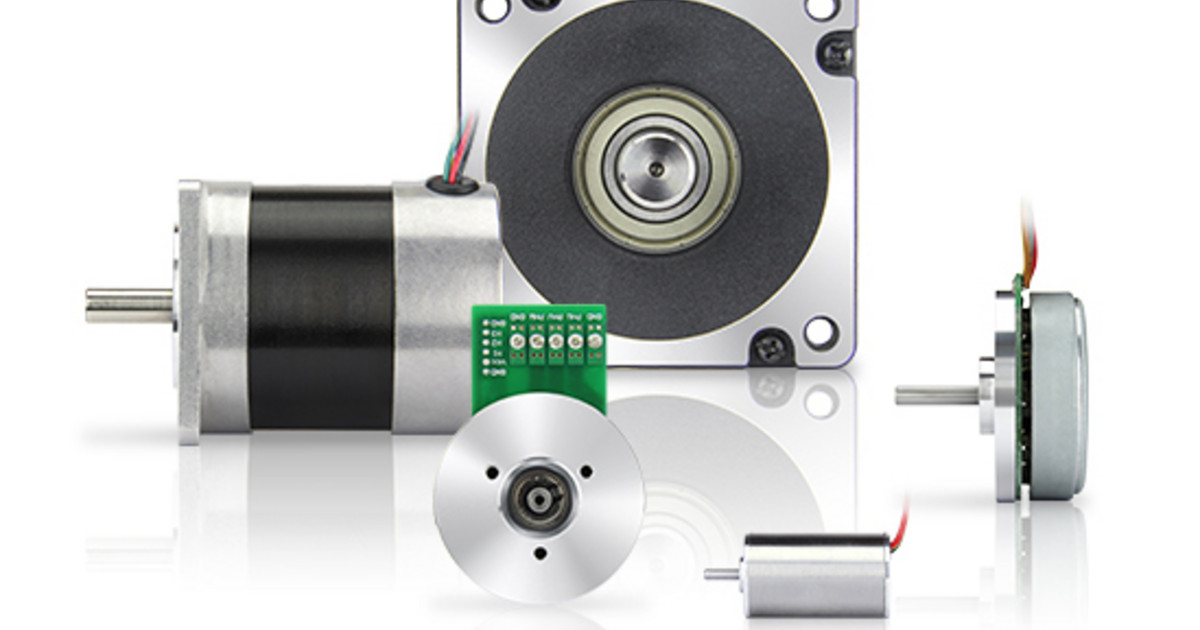

I am in need of a stepper motor with a high RPM ( 750 or higher ). The motors I have been testing tops out at about 300 RPMS.

So the question is there a motor out there that can achieve this speed?

I can not use a normal motor because the shaft only rotates about 90 Deg to 300 Deg then back to the start position at different speeds..

I am using DRV8825 driver chip, controlled with a Raspberry 3.3B and Python.

So the question is there a motor out there that can achieve this speed?

I can not use a normal motor because the shaft only rotates about 90 Deg to 300 Deg then back to the start position at different speeds..

I am using DRV8825 driver chip, controlled with a Raspberry 3.3B and Python.