Hello People

Thanks for taking the time to look at my question

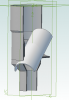

I modeled a reducing tee, then a half tube and placed it in the location i want it to occupy in the end.

The goal is to work out the shape of the half tube so it will fit inside the tee. But despite a few of trying to figure out a way to do it I get either errors or just it just fails to draw. So many ways I tried nothing worked

Any suggestions?

BTW I had to export the tee, then import it to even get the ability to do section view.

I can supply more files if need be

Thanks

Tim

Thanks for taking the time to look at my question

I modeled a reducing tee, then a half tube and placed it in the location i want it to occupy in the end.

The goal is to work out the shape of the half tube so it will fit inside the tee. But despite a few of trying to figure out a way to do it I get either errors or just it just fails to draw. So many ways I tried nothing worked

Any suggestions?

BTW I had to export the tee, then import it to even get the ability to do section view.

I can supply more files if need be

Thanks

Tim