David, thanks for your input. I have worked on this since Friday and it hasn't been easy, but I have learned enough to report my findings. I reread the Alibre Help article on configurations in a BOM, and it really isn't much help. I started out by making a test assembly with two configurations, consisting of a part and a subassembly, each of which has two configurations. Both assembly configs. were inserted into a drawing. I added a config. column to my basic BOM, arranged thusly:

ITEM CONFIG. QTY. DESCRIPTION. After much work, which I will explain later, I got this to work, and saved it as a new BOM template option.

However, this is not what I was trying to do. As mentioned in my question, I want to maintain a simple traditional BOM, consisting of: ITEM QTY. DESCRIPTION, with each configuration listed with its item number, quantity, and description in its own row. Can this be done? As it turns out, yes it can: there is a work-around. Whether or not the effort is worthwhile is a matter of personal preference. What I ended up doing was to insert a column into a BOM using the Configuration property, but then naming it DESCRIPTION as the header title. Then of course you have to name each Configuration in any part or subassembly that you want to appear in the BOM with the description as you want to see it appear in the BOM. This works, and is probably not any more work than doing it some other way, since you have to enter the information somewhere anyway. Of course you can always enter BOM content manually, but if you do, it will not be parametric.

The preceding is description and explanation. What follows is complaint and criticism. If Alibre is your favorite software program, then skip this part because I am not writing this with the intention of offending anyone. I discovered four problems in my learn-by-doing exercise:

1. First, when you use the New Bill of Materials toolbar button, there is a dropdown box to allow the selection of one, and only one, configuration. When you hit Apply, it only inserts that one config., but not any additional configs. that may be in the solid model. As it turns out, you have to save the BOM, which you do when you exit the BOM editor, and then restart the New Bill of Materials dialog, and choose the next config. that is in the solid model, edit the BOM as required, and then exit and save that, apparently for each config. of the same part in the model. What's up with that? Haven't the programmers discovered check boxes (for each config.) yet? This is a tedious and somewhat error prone process. Why not just do it just one time? Or am I missing something, which I acknowledge is very possible. But there is more.

2. For some reason there are two BOM insertion toolbar buttons: the one that I just mentioned, New Bill of Materials, and Insert Bill of Materials. Not being very observant, it took me awhile to notice that there is a difference between the two dialog boxes, which are otherwise identical. At the bottom of the New Bill of Materials dialog is a radio button labeled "New Bill of Materials template". I never did try this button and don't know what it does. At the bottom of the Insert Bill of Materials dialog is a radio button labeled "Existing Bill of Materials". I finally figured out that by using the New Bill of Materials dialog twice, once for each config. in my test drawing as described above, I could assemble, edit and save a BOM, but not insert it into the drawing. Instead, to insert the BOM into the drawing required using the Insert Bill of Materials dialog with the "Existing Bill of Materials" radio button selected. Now while this worked, it is very convoluted, not at all intuitive, and quite time-consuming. It seems like the whole process should be simplified. In particular, why not combine the two dialogs into one. And where is the Help information to cover all of this? Or have I missed something?

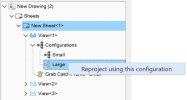

3. The third problem that I encountered may actually be a bug. I noticed a minor error in the description names that I gave to each of the two configurations names in the one part in the assembly: I had left out a space following a comma in each config. name. I closed the drawing, opened the part, made both corrections, saved and closed the part, and reopened the drawing. One BOM line was corrected but the other was not. Reprojecting the drawing made no change. So I did what I had done every time that I couldn't get things to work: I unlinked the BOM which deletes it, closed the drawing and Alibre, deleted the BOM from the drawing folder, copied the new BOM template into the drawing folder and renamed it, reopened Alibre and the drawing, and finally went through the process of inserting a new BOM, as described above. This time both lines had been updated. Again, tedious, error-prone, and time-consuming.

4. Finally, each time I unlinked and thus deleted the BOM the Item balloons lost their registration, showing only a question mark: that is to be expected. However, after a new BOM was inserted, the Item balloons did not automatically reregister (refresh), and the question marks remained, requiring manual updating. This suggests to me that they are not parametric, and it seems to me that they should be.

Alright, I'm done: I've worn myself out trying to document my experiences. The fact that there was only one response to my initial post, and yet many views, suggests a lack of interest by Forum users in this topic, and that includes me, as well: this is not what I want to be doing. And yet I have taken the time in the hope that if my remarks are regarded as having some merit that an administrator will pass them on to the programmers. Regards, Dave