motoxmuseum

Member

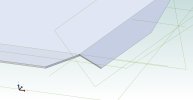

I am trying to duplicate a part that has several different angles. I am trying to reproduce the design using planes and extrusions along the plane vs along normal. However, how do I mate two sections that are on too different planes?

I have attached a picture of the overall part in case there is a better strategy to duplicate the part.

Thanks

I have attached a picture of the overall part in case there is a better strategy to duplicate the part.

Thanks