Hey guys!

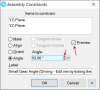

I'm new here and just messing around with my new Atom3d. I worked through the "Alibre Atom3d Exercise Manual" which gave a rather good introduction for somebody who never used a CAD software before. Right now a found a spur gear template in the depth of this forum. Atom3d seems to lack the "configuration" why the gears can't be modified. I will attempt to design one on my own, however, I was wondering whether there will be proper constraints in assembly to actually simulate the gears meshing. I still habe some troubles folding my mind about the whole quick constrain thing.

Cheers singultus

I'm new here and just messing around with my new Atom3d. I worked through the "Alibre Atom3d Exercise Manual" which gave a rather good introduction for somebody who never used a CAD software before. Right now a found a spur gear template in the depth of this forum. Atom3d seems to lack the "configuration" why the gears can't be modified. I will attempt to design one on my own, however, I was wondering whether there will be proper constraints in assembly to actually simulate the gears meshing. I still habe some troubles folding my mind about the whole quick constrain thing.

Cheers singultus