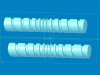

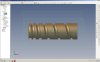

# cylinder dimensions

Diameter = 20

Length = 100

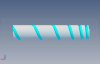

# cutter dimensions

CutterDiameter = 5

# angle to increase by on each pass of the cutter, in degrees

# must be a whole divisor of 180

StepAngle = 10

# total angle of cutting around the cylinder

TotalAngle = 1440

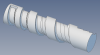

# starting distance from end of cylinder

StartX = 10

# create the cylinder

P = Part("Cylinder")

CylPlane = P.GetPlane("XY-Plane")

CrossSection = P.AddSketch("Cross-Section", CylPlane)

CrossSection.AddCircle(0,0, Diameter, False)

P.AddExtrudeBoss("Cylinder", CrossSection, Length, False)

# create the planes

Planes = []

NumPlanes = 180 / StepAngle

for PlaneIndex in range(0, NumPlanes):

Angle = PlaneIndex * StepAngle

Pl = P.AddPlane("P" + str(Angle), P.GetPlane("YZ-Plane"), P.GetAxis("Z-Axis"), Angle)

Planes.append(Pl)

for PlaneIndex in range(0, NumPlanes):

Planes.append(Planes[PlaneIndex])

NumPlanes = NumPlanes * 2

# start of helix has no offset along cylinder

XStep = 0

# create circle sketches then extrude cut 'through all'

for Step in range(0, TotalAngle / StepAngle):

Angle = Step * StepAngle

NormalizedAngle = Angle % 360

XStep += (Angle * 0.001)

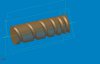

if NormalizedAngle < 90:

X = -(StartX + XStep)

Y = Diameter / 2.0

elif NormalizedAngle == 90:

X = -(Diameter / 2.0)

Y = -(StartX + XStep)

elif NormalizedAngle < 180:

X = (StartX + XStep)

Y = -(Diameter / 2.0)

elif NormalizedAngle < 270:

X = -(StartX + XStep)

Y = -(Diameter / 2.0)

elif NormalizedAngle == 270:

X = (Diameter / 2.0)

Y = -(StartX + XStep)

else:

X = (StartX + XStep)

Y = Diameter / 2.0

Sk = P.AddSketch("S" + str(Angle), Planes[Step % NumPlanes])

Sk.AddCircle(X, Y, CutterDiameter, False)

P.AddExtrudeCut("S" + str(Angle), Sk, 0, False, Part.EndCondition.ThroughAll, None, 0, Part.DirectionType.Normal, None, 0, False)