You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sheet metal conversion?

- Thread starter nvanlaar

- Start date

Nick - I just tried it here, opened (and saved) your part, selected convert to sheet metal, clicked 'replicate sheet metal part' - all worked fine.

I appear to be using same version of GD as you - also running Win10.

I did notice when I clicked convert to sheet metal that the initially reported stock thickness was incorrect - this corrected itself when I used 'replicate...'

Maybe the stock thickness initially comes in from your default setting? If thickness and bend radius are incompatible, it is possible that features will get left out. If you are manually driving the conversion check that stock thickness (and hence minimum bend radius) is correct.

[EDIT - yes just confirmed by experiment, stock thickness will initially be set to your default, if I drive the conversion manually and the stock thickness is too great, it fails and misses out the flange - in my example because the inside bend radius would be negative. Check material thickness, or edit minimum bend radius.]

[EDIT 2 - Nick, your settings above look OK though - BUT if you drive conversion manually, GD respects the minimum bend radius (Thickness/2 by default) if you use the Replicate button GD seems to override the minimum bend radius value. If driving this manually, you have to both set the thickness and the minimum bend radius to be compatible with your part.]

I appear to be using same version of GD as you - also running Win10.

I did notice when I clicked convert to sheet metal that the initially reported stock thickness was incorrect - this corrected itself when I used 'replicate...'

Maybe the stock thickness initially comes in from your default setting? If thickness and bend radius are incompatible, it is possible that features will get left out. If you are manually driving the conversion check that stock thickness (and hence minimum bend radius) is correct.

[EDIT - yes just confirmed by experiment, stock thickness will initially be set to your default, if I drive the conversion manually and the stock thickness is too great, it fails and misses out the flange - in my example because the inside bend radius would be negative. Check material thickness, or edit minimum bend radius.]

[EDIT 2 - Nick, your settings above look OK though - BUT if you drive conversion manually, GD respects the minimum bend radius (Thickness/2 by default) if you use the Replicate button GD seems to override the minimum bend radius value. If driving this manually, you have to both set the thickness and the minimum bend radius to be compatible with your part.]

nvanlaar

Senior Member

Nothing happens when I click the replicate button. In fact, if I select a flange and then click replicate, it removes all feature selections and I can't select OK. I can't set the bend radius. I tried and it reverts back to 0.96mm which is what Ralph's screenshot shows. The DIMS are correct... so where does this go awry?

Here are my steps:

1. Open part in GM

2. Select "Convert to Sheetmetal part" (closes part and opens new window with conversion dialog and preview)

3. a. Select "replicate" = nothing happens

b. Select flange (doesn't matter which), select "replicate", flange is then de-selected and nothing happens

c. Select flange

4. Select Bend

5. Set thickness to correct dimension (0.1" or 2.54mm) Preview displays everything correctly

6. Click OK

7. Missing flange (shows error) in mech. browser

Solved?:

I bumped my precision to 6 decimal places.

I then could select a flange and click the replicate button, which then worked and the part was successfully converted.

Here are my steps:

1. Open part in GM

2. Select "Convert to Sheetmetal part" (closes part and opens new window with conversion dialog and preview)

3. a. Select "replicate" = nothing happens

b. Select flange (doesn't matter which), select "replicate", flange is then de-selected and nothing happens

c. Select flange

4. Select Bend

5. Set thickness to correct dimension (0.1" or 2.54mm) Preview displays everything correctly

6. Click OK

7. Missing flange (shows error) in mech. browser

Solved?:

I bumped my precision to 6 decimal places.

I then could select a flange and click the replicate button, which then worked and the part was successfully converted.

nvanlaar

Senior Member

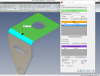

nvanlaar said:I can't set the bend radius. I tried and it reverts back to 0.96mm which is what Ralph's screenshot shows....

I referred to the minimum bend radius in the design properties - any bend in the design with radius smaller than this usually fails. Though from subsequent posts it seems that there is another issue too.

JST

Alibre Super User

DavidJ said:Nick - I just tried it here, opened (and saved) your part, selected convert to sheet metal, clicked 'replicate sheet metal part' - all worked fine.

I get this same result with same procedure. Part converts fine, I was able to make a drawing of it, etc. Win 7, 2015.0.1 32 bit.

This should be significant, because I am a definite "bug-magnet", AND I have not used sheet metal much since the first trial version of full V16 I used for a while earlier this year. If it works for me, it should work for you.

I had to let it use the "AD default bend radius", which turned out to be what was in the original part. If I tried to put in a radius, it failed, but not the way your attempt failed. Didn't matter if the radius was LARGER. Presumably the issue is that it wants to use the radius SHOWN IN THE PART YOU CONVERT due to the use of "replicate" modifier, which accepts the input geometry.