silver2row

Senior Member

Hello,

As some of you know, I am a fanatic regarding bolts in general. As I have learned some movements and rules in Alibre, I have also come across some distinct errors in the software...

Please hear me out here.

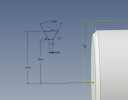

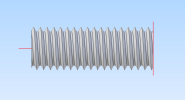

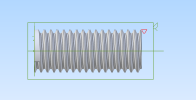

So, I make a cylinder out of an extruded circle. I then guide my line making behavior in the 2D sketch. I make a triangle or a quadrilateral with unequal sides at 60 degrees for the...oh. I think I just figured out the issue(s)...

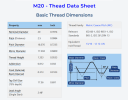

I was making my diagonal lines 60 degrees instead of the top line to be 60 degrees with the parallel line to the top line (Pitch/4).

Blah...

Seth

P.S. I need to watch the videos again and rehearse. If you want to reply, okay. If not, okay too.

As some of you know, I am a fanatic regarding bolts in general. As I have learned some movements and rules in Alibre, I have also come across some distinct errors in the software...

Please hear me out here.

So, I make a cylinder out of an extruded circle. I then guide my line making behavior in the 2D sketch. I make a triangle or a quadrilateral with unequal sides at 60 degrees for the...oh. I think I just figured out the issue(s)...

I was making my diagonal lines 60 degrees instead of the top line to be 60 degrees with the parallel line to the top line (Pitch/4).

Blah...

Seth

P.S. I need to watch the videos again and rehearse. If you want to reply, okay. If not, okay too.