bolsover

Senior Member

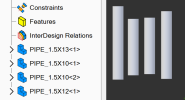

So I've been testing out the new toolbox feature and have to say I'm quite impressed. I can see that this will be of great benefit for all users once there is a body of 'standard' part toolbox items available. @Max has already suggested that there may be some dedicated file space available in the future. I know also know that there are a couple of items already in the resources area of the forum.

I've already reported on bug in toolbox - and had a very positive reply from support.

I think there are a couple of other issues with the system that need to be addressed but which are not actually bugs.

Just my view but here are a few possible areas for improvement:

1 When adding a toolbox item to an assembly, having navigated to the toolbox part I want, I then have to click on the 'configure and insert' button. I would make sense if I just had to double click the selected item to open up the insert dialog.

2 If I want to edit an existing toolbox part to add or make changes to the selection criteria, the part 'Save' button is disabled, I have to do a 'Save as' and overwrite the existing part. I understand the rationale behind this - but it seems - well a bit clunky. I would prefer to see a warning dialog 'Are you sure you want to replace toolbox part?'

3 If I design a toolbox part and go though the 'Add Part from Spreadsheet' routine, design the Part and set up everything only to realise I need one more parameter - I need to start all over with a new part design. It would be really helpful If I could save the work in progress, make the necessary changes to the spreadsheet and then re-read the fields into the now existing but incomplete part design.

David

I've already reported on bug in toolbox - and had a very positive reply from support.

I think there are a couple of other issues with the system that need to be addressed but which are not actually bugs.

Just my view but here are a few possible areas for improvement:

1 When adding a toolbox item to an assembly, having navigated to the toolbox part I want, I then have to click on the 'configure and insert' button. I would make sense if I just had to double click the selected item to open up the insert dialog.

2 If I want to edit an existing toolbox part to add or make changes to the selection criteria, the part 'Save' button is disabled, I have to do a 'Save as' and overwrite the existing part. I understand the rationale behind this - but it seems - well a bit clunky. I would prefer to see a warning dialog 'Are you sure you want to replace toolbox part?'

3 If I design a toolbox part and go though the 'Add Part from Spreadsheet' routine, design the Part and set up everything only to realise I need one more parameter - I need to start all over with a new part design. It would be really helpful If I could save the work in progress, make the necessary changes to the spreadsheet and then re-read the fields into the now existing but incomplete part design.

David