OTE_TheMissile

Alibre Super User

I feel like I might've asked this ages ago when I was active on these forums after first taking this job in 2008, but I can't figure out how to find my old threads from back then...

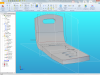

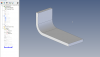

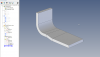

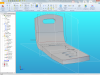

We have this bracket that we farm out to a laser shop to get cut & bent, and today a fresh batch of them came across my desk for inspection upon arrival. Last time I looked at the print for these was in 2013 according to the revision notes and I remember having to fudge a twist feature for the model using a Loft. The result looks pretty enough but I can't Flatten it with the straight bend and had to do double the amount of fudging for the print to get the layout view.

That was then and this is now, and I'd like to think I'm a better Alibre CAD tech than I was, so is there a less-stupid way of doing this nowadays so the twist can be Flattened like a regular Sheetmetal feature?

We have this bracket that we farm out to a laser shop to get cut & bent, and today a fresh batch of them came across my desk for inspection upon arrival. Last time I looked at the print for these was in 2013 according to the revision notes and I remember having to fudge a twist feature for the model using a Loft. The result looks pretty enough but I can't Flatten it with the straight bend and had to do double the amount of fudging for the print to get the layout view.

That was then and this is now, and I'd like to think I'm a better Alibre CAD tech than I was, so is there a less-stupid way of doing this nowadays so the twist can be Flattened like a regular Sheetmetal feature?