Hi Alibre community,

I'm new to Alibre, and have been having a blast learning how to use it (it reminds me a lot of Fusion360, but with a much better licensing scheme!)

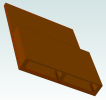

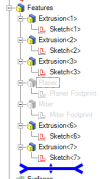

I'm working on a simple "flip top table" design (all the rage on YouTube nowadays). My design will be built using 1/2" plywood and 2x4s. My first though was to design the table top, sans the table legs, in Alibre Atom. It was easy to do with a few sketches:

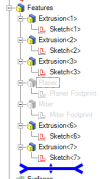

The next thing I wanted to do was render each feature in my design drawing (see features below)

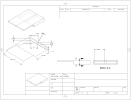

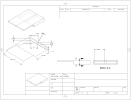

Unfortunately, I can't seem to figure out how to do this. Here's what my drawing looks like today:

Ideally I'd be able to render each feature independently, to build a cultist so to speak. I suspect I'm just approaching the problem incorrectly, so I'm happy to learn about the correct way to do this - even if it means upgrading my license or investing in 3rd party software...

Best,

Jon

I'm new to Alibre, and have been having a blast learning how to use it (it reminds me a lot of Fusion360, but with a much better licensing scheme!)

I'm working on a simple "flip top table" design (all the rage on YouTube nowadays). My design will be built using 1/2" plywood and 2x4s. My first though was to design the table top, sans the table legs, in Alibre Atom. It was easy to do with a few sketches:

The next thing I wanted to do was render each feature in my design drawing (see features below)

Unfortunately, I can't seem to figure out how to do this. Here's what my drawing looks like today:

Ideally I'd be able to render each feature independently, to build a cultist so to speak. I suspect I'm just approaching the problem incorrectly, so I'm happy to learn about the correct way to do this - even if it means upgrading my license or investing in 3rd party software...

Best,

Jon