dlaery

Alibre Super User

I use the gear geanerator but I don't know how to draw to a gear to a certain diameter.

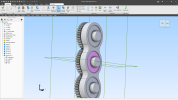

this will be 3 gears in a row

I need them to be 1.85 inches..

is scaling an acceptable way to get the size I want?

ok, now I realize that Pitch diameter is what I want to use to get the right diameter.

What does the DP and Module represent?

NumberofTeeth = 20

Module = 1.5

PressureAngle = 20

Thickness = 3

NumberofTeeth = 20

DP = 24

PressureAngle = 20

Thickness = 3

this will be 3 gears in a row

I need them to be 1.85 inches..

is scaling an acceptable way to get the size I want?

ok, now I realize that Pitch diameter is what I want to use to get the right diameter.

What does the DP and Module represent?

NumberofTeeth = 20

Module = 1.5

PressureAngle = 20

Thickness = 3

NumberofTeeth = 20

DP = 24

PressureAngle = 20

Thickness = 3