Recent content by steveastro

-

S

Traced image as the basis for an assembly

I COULD, but I was trying to avoid that, to ensure complete synchronisation with the underlying image.- steveastro

- Post #3

- Forum: Using Alibre Design

-

S

Traced image as the basis for an assembly

I am trying to use a traced, scaled image as the basis to build multiple components for a boat model. I can create a tracing image in a new assembly. My plan had been to create a part in the assembly, then edit the part within the assembly, and trace it off the tracing image. When I try though...- steveastro

- Thread

- Replies: 4

- Forum: Using Alibre Design

-

S

Best approach for this part

Ah ! No, but that looks like make the sort of approach I was thinking of. Thanks Stefan.- steveastro

- Post #13

- Forum: Using Alibre Design

-

S

Best approach for this part

Whilst the conversation is interesting and informative, its seems to me, that the simplest way to do this would be a mechanism to automatically use a master sketch as the foundation for the works on the part, and there doesn't appear to be a mechanism for it.- steveastro

- Post #10

- Forum: Using Alibre Design

-

S

Best approach for this part

Revolves are my preferred way of working with parts like this. I find it easy to visualise.- steveastro

- Post #8

- Forum: Using Alibre Design

-

S

Best approach for this part

I too find it a PITA when the origin of a new part is displaced like this, but it seems fundamental to the arrangement of parts in an assembly that stays properly constrained.- steveastro

- Post #7

- Forum: Using Alibre Design

-

S

Best approach for this part

Yes, Top Down, there is a complex optical layout which affects the relative positions of the lens, mirrors and focal plane of the system, and which is spreadsheet driven.- steveastro

- Post #5

- Forum: Using Alibre Design

-

S

Best approach for this part

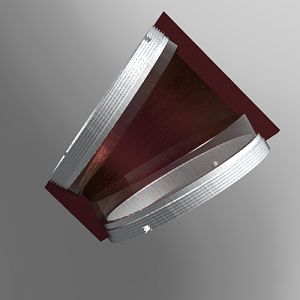

I've attached what is a special lens cell for an optical project. If someone would like to look, at its heart is a sketch tied to a 2D arrangement of lenses tipped and shifted to each other. There is no single rotation of cut that would make this, so the second and third sketches are rotated...- steveastro

- Thread

- revolve

- Replies: 12

- Forum: Using Alibre Design

-

-

S

Working with large hexagonal mesh

Will look at your suggestions. Thanks. Never have got to grips with "topology pattern" - now might be the time ! I tried a large sketch, and I tried feature pattern. I think there is probably a sweet spot somewhere, but I didnt find it. I also tried removing all the consraints in the sketches...- steveastro

- Post #11

- Forum: Using Alibre Design

-

S

Working with large hexagonal mesh

We had a smaller part (this is part of a family) made last week very economically with a fibre laser. The laser was running at 400 IPS. Each part which you can reckon being 9 x12 " or so, took less than 10 minutes. The final profile for the part ran at 1200 IPS. The final cost of the part was...- steveastro

- Post #10

- Forum: Using Alibre Design

-

S

Working with large hexagonal mesh

Hi Lew Here's a sample of the piece.Its only a small sample. The mesh has to be in-phase across all the filled pockets, so I have made a piece of hex material as a separate part which I cut out with a sketch of all the pocket outlines, then boolean unite into the model of the part.- steveastro

- Post #3

- Forum: Using Alibre Design

-

S

Working with large hexagonal mesh

I have a sheet metal part which, when its finished, will be perforated with 6.5mm AF hexagonal mesh - the part is fairly big, about 450mm x 450mm, and my mesh keeps breaking Alibre to the point of crashing. How can I improve the performance ?I've tried to use more sketches of meshes, and fewer...- steveastro

- Thread

- Replies: 11

- Forum: Using Alibre Design

-

S

Sheet metal tutorials

Harold, I didn't realise unbend was as useful as you show it ! Lew, thanks, I'll play with Harold's files and see if that fixes my current issue. Steve- steveastro

- Post #5

- Forum: Using Alibre Design

-

S

Sheet metal tutorials

Are there any decent tutorials on using the Sheet metal tools ? I have a part with a long edge (say 150mm) from which I need to have two narrower flanges, say 25mm long each, one 20mm from one end of the long edge, the other 60mm from the same edge. Every time I have made a flange and then...- steveastro

- Thread

- Replies: 4

- Forum: Using Alibre Design