silver2row

Senior Member

Hello,

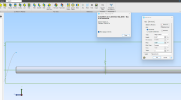

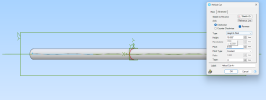

As some of you may know, I am new to the idea of drawing mechanical instances. I have been following along in videos and learning Alibre Atom3D (my current subscription) by way of tutorials recently to learn more.

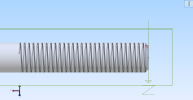

So, in the bolt video, https://www.alibre.com/atom3d-training/ , I see there is not a set of threads...

Has anyone mastered this portion of the builds without resorting to https://www.traceparts.com/en or another building appliance from different sites online.

I watched the video. I will perform the actions soon. If anyone knows of some steps to take to create threaded components, I would be most pleased!

Seth

P.S. Thank you for your consideration...

As some of you may know, I am new to the idea of drawing mechanical instances. I have been following along in videos and learning Alibre Atom3D (my current subscription) by way of tutorials recently to learn more.

So, in the bolt video, https://www.alibre.com/atom3d-training/ , I see there is not a set of threads...

Has anyone mastered this portion of the builds without resorting to https://www.traceparts.com/en or another building appliance from different sites online.

I watched the video. I will perform the actions soon. If anyone knows of some steps to take to create threaded components, I would be most pleased!

Seth

P.S. Thank you for your consideration...