I have been building a large standoff with metric type threads. Anyway, here it is...

Also...not just showing off ideas but indulging in other ideas where I cannot change things in my Alibre Atom3D source:

The shoulder bolt photo of a CAD drawing below has me thinking of "how!"

What I was sold and what is listed are similar but not quite the same.

My main concern is the utilization of other technical skills relating to the shoulder bolt...

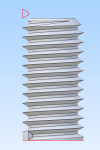

1. A line through the middle allows for extra advancement

2. It is almost like there are two lines on many planes.

a. One for intersection and another opposite for intersection of threads, the actual shoulder, and smaller-noticeable built parts like the interior hex in the head.

b. There are

lines, with a perspective from photo viewing definitions, within the threads that run 60 to 55 degrees.

3. The

lines in the threads are

helix angles in between the

crest(s) and

root(s).

Anyway, here it is below. I am maybe wrong with respect to the

lines of the

helix angles that do or do not exist in the above diagram/CAD.

I am knowingly "gibberish'ing" here and I dislike as much as others do but...

1. I want to learn more about bolt building.

2. I first wanted to learn CAD with thinking it could turn me into an advantageous user and builder.

3. "Fitting in is half the battle!"

Seth

P.S. Does anyone know how to root and crest the planes on threads and if so, is anyone willing to help or create a group for others like me who want to learn? I am new and probably creating a too-much, too-soon scenario. Okay. Done for now.