silver2row

Senior Member

Hello @HaroldL ,

I noticed in the Equal Constraint icon usage, one would need to have two pieces instead of altering just one piece (closed or open). I also saw that the double lines I can use for the Equal Constraint icon does not work for me. For a reason, I understand but I do not know this reason for now.

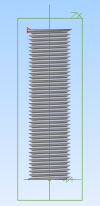

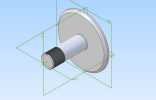

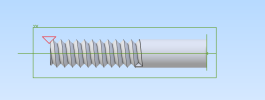

So far, I have a 40mm * 12mm cylinder with parallelogram for my cutting of the threads. I have been unable to perform an Equal Constraint use from the docs. pages for some reason.

With this parallelogram, I am planning on tuning it into a triangle to make it so the threads cut.

Seth

P.S. Is there some trick I am missing into making a triangle that can be used instead of what I have currently and how would I achieve this idea? I use the line tool for triangle making. When I try to use the Equal Constraint with the two or three line triangle, I get dumbfounded. The change cannot happen. Anyway, thank you for your consideration so far. I appreciate the support.

I noticed in the Equal Constraint icon usage, one would need to have two pieces instead of altering just one piece (closed or open). I also saw that the double lines I can use for the Equal Constraint icon does not work for me. For a reason, I understand but I do not know this reason for now.

So far, I have a 40mm * 12mm cylinder with parallelogram for my cutting of the threads. I have been unable to perform an Equal Constraint use from the docs. pages for some reason.

With this parallelogram, I am planning on tuning it into a triangle to make it so the threads cut.

Seth

P.S. Is there some trick I am missing into making a triangle that can be used instead of what I have currently and how would I achieve this idea? I use the line tool for triangle making. When I try to use the Equal Constraint with the two or three line triangle, I get dumbfounded. The change cannot happen. Anyway, thank you for your consideration so far. I appreciate the support.