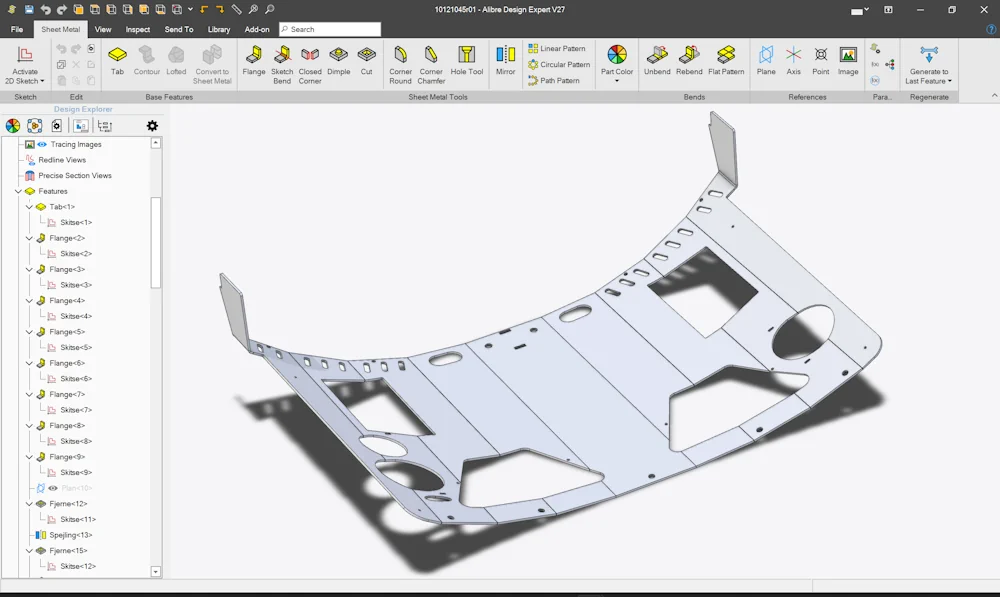

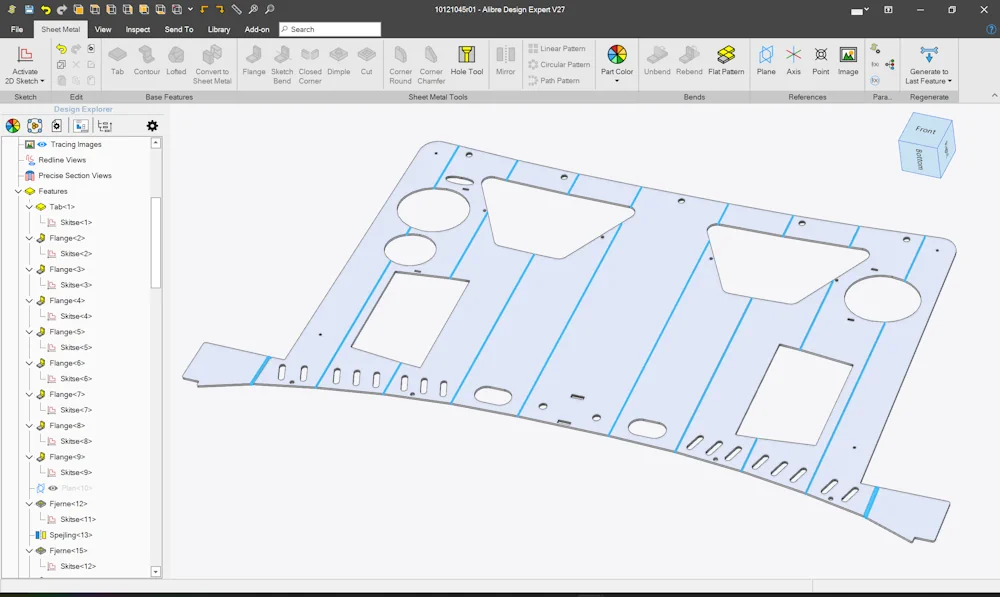

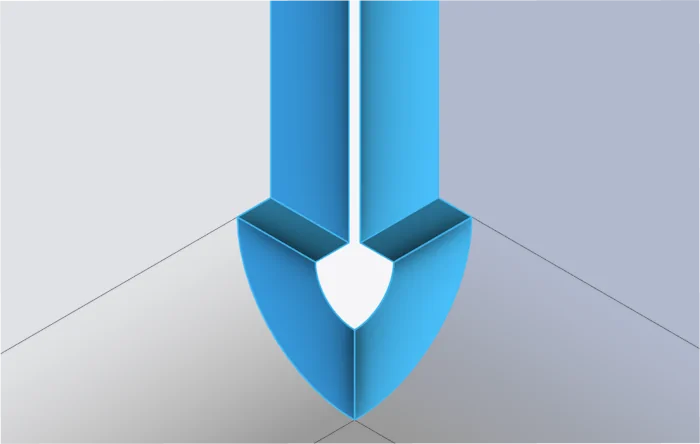

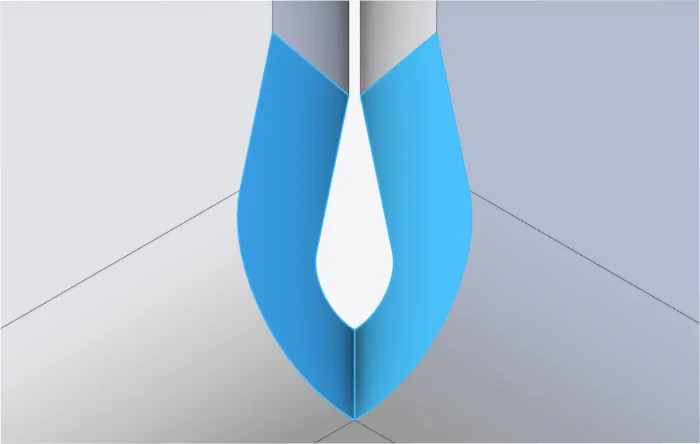

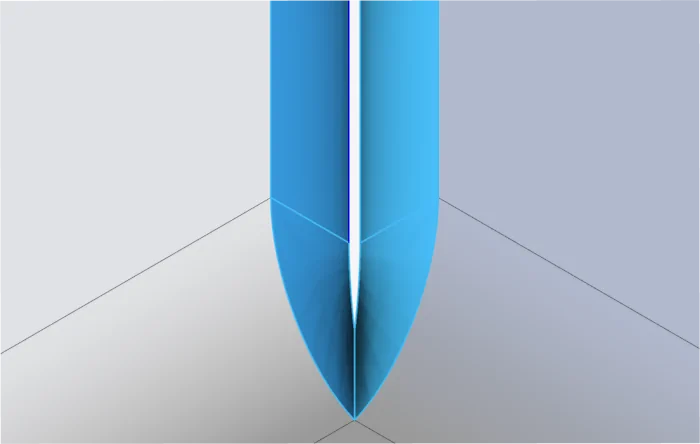

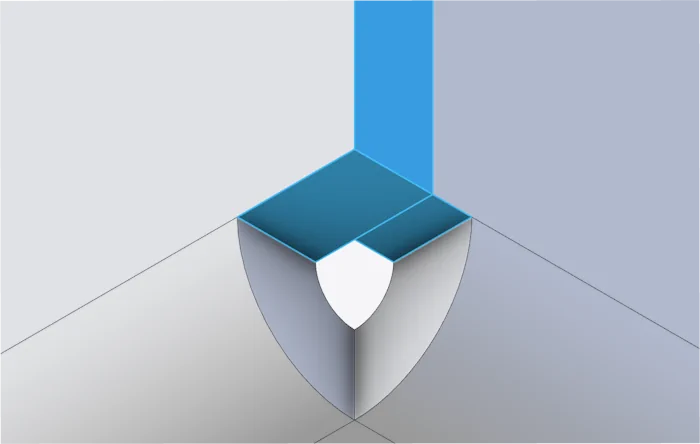

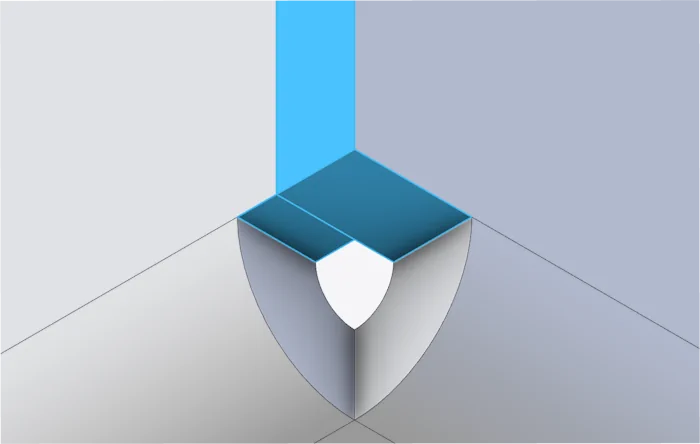

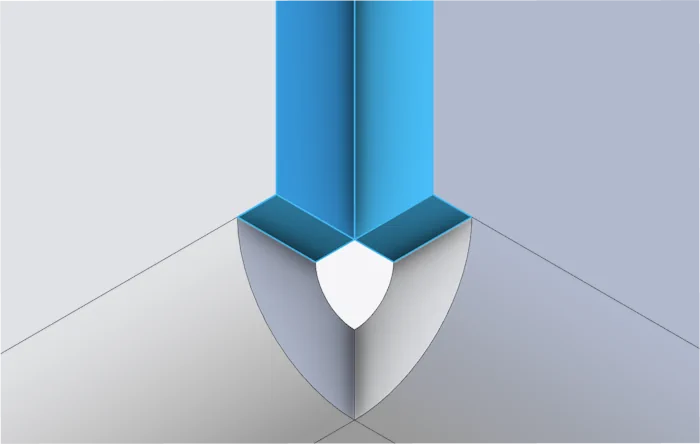

Lofted Transitions

Create complex, manufacturable transitions between dissimilar profiles in a completely automated workflow.

Wizard completely automates creation of lofted transition components.

All lofted components can be flattened for cutting and bending documentation.

Square, rectangle, circle, and ellipse end profiles - choose any combination.