Table of Contents

TopicsBenefits of CAM

Today, machining and software go hand in hand. Recognizing the benefits of some of the most prevalent machining software is the first step toward designing and manufacturing with more precision, higher efficiency and fewer errors.

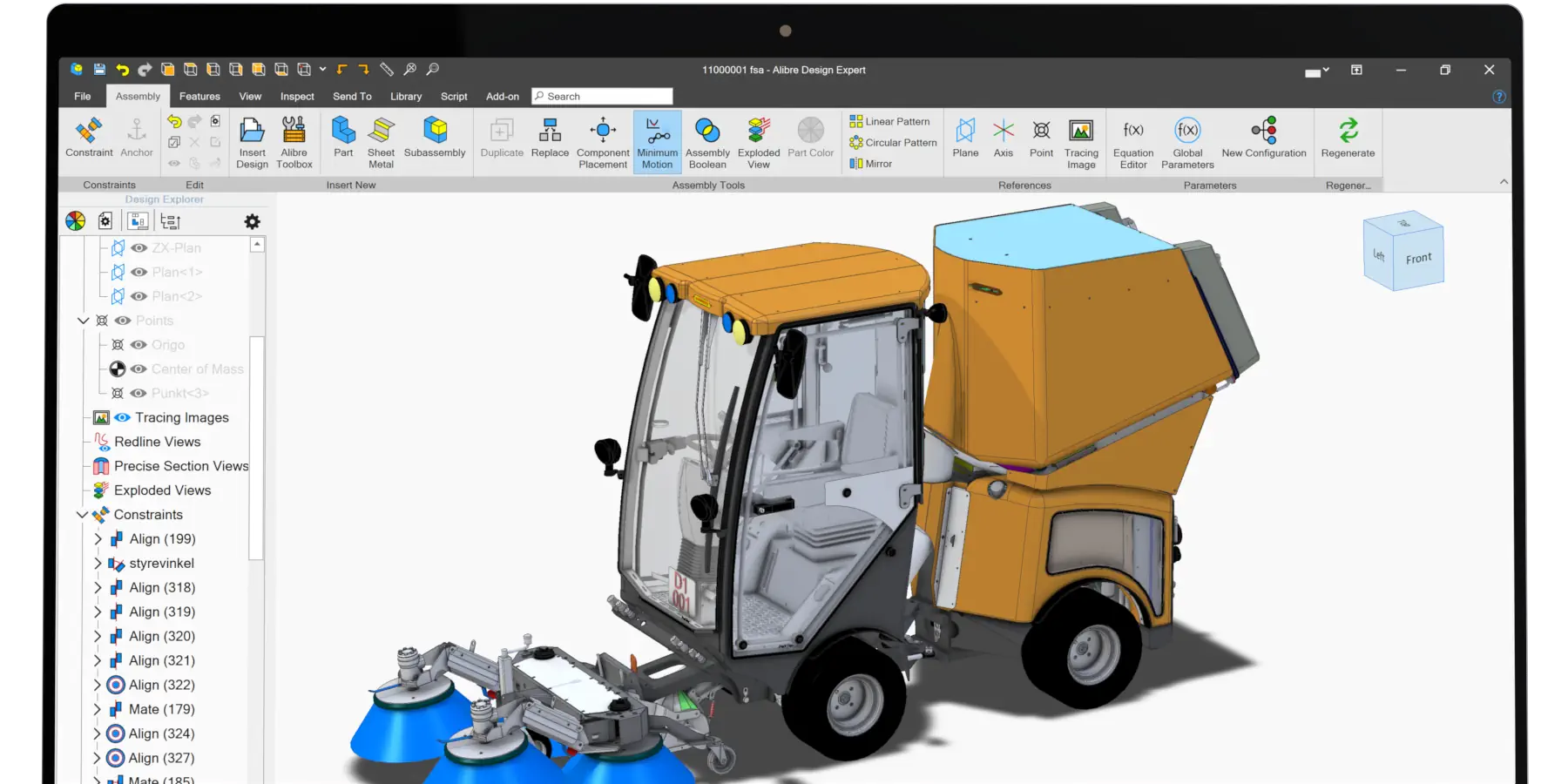

Computer-aided manufacturing, or CAM, is the use of software to plan and control machinery operations. CAM software converts 3D models into toolpaths which in turn tell mills, lathes, routers, wire EDM machines and more how to move. CAM works by translating computer-aided designs (CAD) into instructions that machines can understand and implement. By tightening the design-to-machine process, CAM increases manufacturing efficiency and reduces mistakes so you can get the most out of your machines, materials and time.

Computer-aided manufacturing, or CAM, is the use of software to plan and control machinery operations. CAM software converts 3D models into toolpaths which in turn tell mills, lathes, routers, wire EDM machines and more how to move. CAM works by translating computer-aided designs (CAD) into instructions that machines can understand and implement. By tightening the design-to-machine process, CAM increases manufacturing efficiency and reduces mistakes so you can get the most out of your machines, materials and time.

CAM Saves Time and Streamlines Workflows

One of the greatest advantages of CAM software is how compatible it is with other steps in the manufacturing process. Creating a product includes two main steps — design and manufacture. CAM and CAD use the same computerized systems of converting geometrical data, closely integrating those two processes. By communicating effectively, CAM and CAD allow for streamlined production that requires less time between design and manufacture. Other time-saving benefits and features include:

Working with the same data

CAM software typically has an input of 3D geometry or 2D geometry. CAD software excels at creating both of these geometry types. Transitioning from CAD to CAM is typically relatively seamless for this reason

Manufacturing intelligence

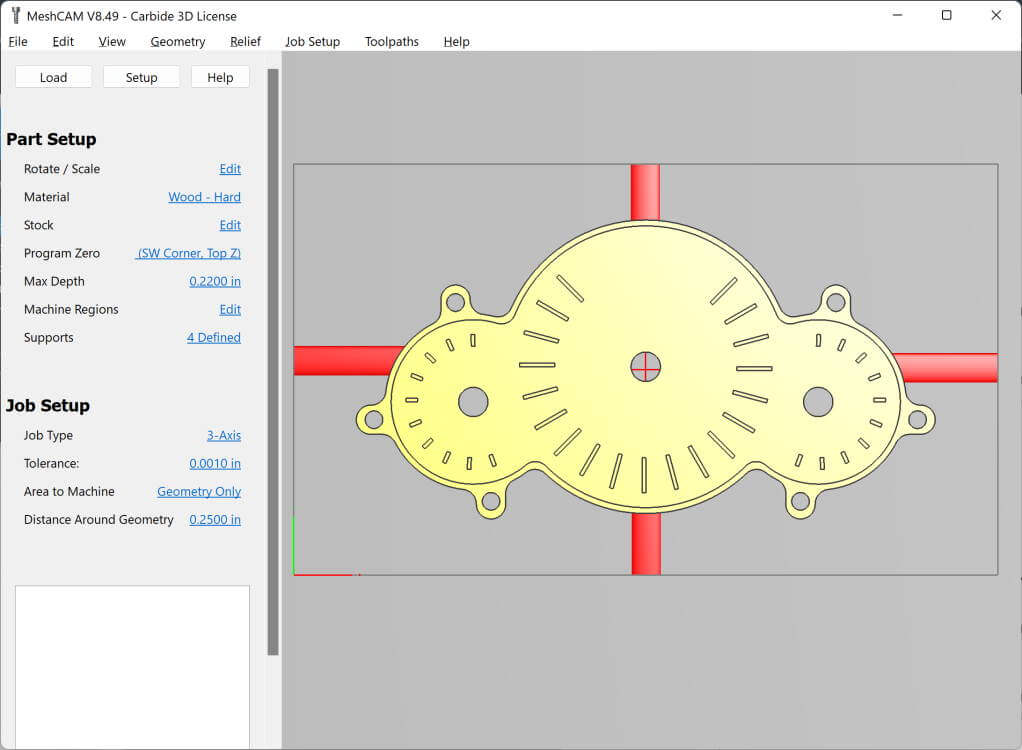

When creating toolpaths you must be aware of a few key pieces of information - the material you're cutting, the type of bit you're using, the capabilities of your machine, and a few more. Combining all this data results in setting a few key parameters, known typically as the feeds and speeds. Feeds and speeds tell the machine how fast to move and how fast to spin - two things that must be in the right ballpark to successfully machine a part with good surface finish and to extend bit life. Some CAM software has built-in intelligence that automates much of this process.

Machining Simulations

When translating designs into manufacturing operations, you want to have all the details exactly right. There's a lot to keep track of when picturing what kind of product a design plan might produce. One unique benefit of CAM is its capacity for machining simulations.

The information CAM receives from CAD includes the dimensions and shape of the product you're manufacturing. CAM verifies this information then generates tool paths and translates them into a numerical control (NC) program that's specific to the machine you're using.

Prior to using a CNC machine to start cutting material, you can use CAM to simulate the toolpaths virtually. The simulation shows you a preview of what the manufacturing process will look like, so you can make adjustments to the program before production begins.

The information CAM receives from CAD includes the dimensions and shape of the product you're manufacturing. CAM verifies this information then generates tool paths and translates them into a numerical control (NC) program that's specific to the machine you're using.

Prior to using a CNC machine to start cutting material, you can use CAM to simulate the toolpaths virtually. The simulation shows you a preview of what the manufacturing process will look like, so you can make adjustments to the program before production begins.

Improve Client Accessibility

Before CAM technology, toolmakers designed manufacturing equipment using paper and pencil. If your business is still using this method, consider the cost of human error. Hand-drawn designs can be difficult to interpret and communicate to others, leading to missing or mistranslated information and products that reflect those issues.

Today's software has eliminated a number of those issues. CAD and CAM can easily exchange data to each other. When clients create a design using CAD and you receive this design, you can start manufacturing right away, implementing the data to create the necessary machining paths, tool lists and tool positions.

Manufacturing is a collaborative process at every step, and you want your clients to be pleased with the quality of the products you create. Easier communication from the design to the manufacturing process means faster turnaround times and giving clients just what they're looking for the first time around.

Today's software has eliminated a number of those issues. CAD and CAM can easily exchange data to each other. When clients create a design using CAD and you receive this design, you can start manufacturing right away, implementing the data to create the necessary machining paths, tool lists and tool positions.

Manufacturing is a collaborative process at every step, and you want your clients to be pleased with the quality of the products you create. Easier communication from the design to the manufacturing process means faster turnaround times and giving clients just what they're looking for the first time around.

Improve Machine Productivity

CAM helps you get the most out of your machines' capabilities. Since design and manufacture are so closely linked in the CAD/CAM process, you can produce a higher volume of quality products than ever before.

You can create dozens of different toolpaths that all result in the same part being milled. Some of them will be efficient, others will result in tool breakage, some will have good surface finish, and others will take four times longer than they need to. Part of the process of maximizing productivity is crafting machining strategies that are as efficient as possible while maintaining quality surface finish and maximizing tool life. CAM software allows you to try out different ideas and simulate them so you can arrive at the best strategy to maximize productivity.

You can create dozens of different toolpaths that all result in the same part being milled. Some of them will be efficient, others will result in tool breakage, some will have good surface finish, and others will take four times longer than they need to. Part of the process of maximizing productivity is crafting machining strategies that are as efficient as possible while maintaining quality surface finish and maximizing tool life. CAM software allows you to try out different ideas and simulate them so you can arrive at the best strategy to maximize productivity.

Reduce Material Waste

When working with raw materials you want to make sure you get the most out of your stock. Using a combination of CAD and CAM, you can arrange multiple parts together to tightly pack them into a single piece of stock. The precision of CNC machines allows packing to be quite dense, depending on the material you're using, which maximizes how many parts per stock unit you can achieve.

Reduce Mistakes

In the days of hand-designed products, manufacturers risked misunderstanding designs and making time-consuming and costly changes to their machines when trying to produce satisfactory results. Now, with CAM reading CAD designs and efficiently bringing them to life, the design-to-product pathway results in far fewer mistakes.