Table of Contents

TopicsWhy these guidelines are important

Whether you are machining parts yourself our outsourcing, you want to design parts that can be easily (cheaply and quickly) machined while retaining the intended function. Common mistakes made during the design phase can result in unnecessarily costly machining later, or having the design tossed back to you for revisions. Revisions at that stage may then require revisions to other components, resulting in a cascade of things you won't want to be doing or paying for.

Considering these common rules of thumb up front can ensure that the most common design considerations for CNC machining can be implemented during the design stage, saving you time and probably a lot of money and headache. Fix your mistakes in CAD software before sending them down the process chain.

Considering these common rules of thumb up front can ensure that the most common design considerations for CNC machining can be implemented during the design stage, saving you time and probably a lot of money and headache. Fix your mistakes in CAD software before sending them down the process chain.

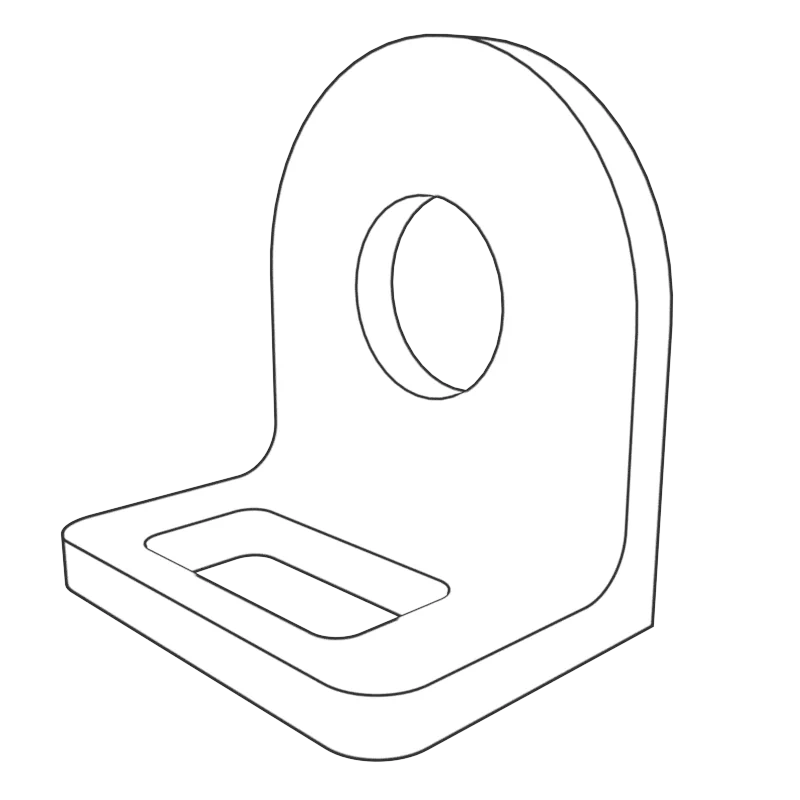

Basic Part Feature Orientation

Feature Orientation Guidelines

The 6 principle axes, ±X ±Y ±Z, are your friends. Where possible, design parts such that walls, holes, and similar features are along these axes.

Features at odd angles often require more expense in fixturing and setup costs, or costlier machining methods such as 5-axis machining.

Feature Orientation Deeper Dive

In CNC machining, tool accessibility is a primary design constraint. To access every surface of the model, the workpiece must undergo several rotations. Each time the workpiece is turned, the machine necessitates recalibration, and a fresh coordinate system is established.

When designing, it's crucial to factor in machine setups for two main reasons:

The cumulative number of setups directly impacts the cost. The process of rotating and repositioning the piece involves manual intervention, prolonging the overall machining duration. While it's generally acceptable for a part to be rotated three or four times, going beyond this can be deemed excessive.

For optimal relative positional precision, it's essential to machine two features within the same setup. This is due to the minor yet potentially significant cumulative error introduced during each recalibration phase.

When designing, it's crucial to factor in machine setups for two main reasons:

The cumulative number of setups directly impacts the cost. The process of rotating and repositioning the piece involves manual intervention, prolonging the overall machining duration. While it's generally acceptable for a part to be rotated three or four times, going beyond this can be deemed excessive.

For optimal relative positional precision, it's essential to machine two features within the same setup. This is due to the minor yet potentially significant cumulative error introduced during each recalibration phase.

Cavities and Pockets in CNC Machining

Quick Cavity and Pocket Guidelines

Maximum cavity and pocket depth: 3-4 times the diameter of the end mill you plan on using.

Cavity and pocket depth is limited primarily by the diameter of your end mill.

To reach deeper into material, a longer end mill must be used.

Longer end mills deflect more, vibrate more, and evacuate chips less efficiently. Typically you need to increase the diameter of the end mill to mitigate these issues.

Cavity and Pocket Design Deeper Dive

When it comes to CNC machining, the depth of cavities and pockets plays a pivotal role in the final product's quality. The general rule of thumb is to have a cavity depth that's four times the width of the endmill you'll be using. Why is this so?

The answer lies in the nature of end mill tools. These tools, essential in CNC machining, have a cutting length that's typically 3–4 times their diameter. When the depth-to-width ratio of a cavity is smaller, challenges such as tool deflection, chip evacuation, and vibrations become more pronounced, potentially compromising the quality of the machined part.

By keeping the cavity depth to about four times its width, these challenges are minimized, ensuring a high-quality result. However, if your design necessitates deeper cavities, it's worth exploring parts with a variable cavity depth to maintain structural integrity.

For those delving into deep cavity milling, where the depth is more than six times the tool diameter, specialized tooling is essential. With the right tools, you can achieve impressive depths—imagine reaching a depth of 35 cm with a 1-inch diameter end mill!

The answer lies in the nature of end mill tools. These tools, essential in CNC machining, have a cutting length that's typically 3–4 times their diameter. When the depth-to-width ratio of a cavity is smaller, challenges such as tool deflection, chip evacuation, and vibrations become more pronounced, potentially compromising the quality of the machined part.

By keeping the cavity depth to about four times its width, these challenges are minimized, ensuring a high-quality result. However, if your design necessitates deeper cavities, it's worth exploring parts with a variable cavity depth to maintain structural integrity.

For those delving into deep cavity milling, where the depth is more than six times the tool diameter, specialized tooling is essential. With the right tools, you can achieve impressive depths—imagine reaching a depth of 35 cm with a 1-inch diameter end mill!

Vertical Internal Corner Radius

Vertical Internal Corner Radius Guidelines

Recommended: At least 1/3 the depth of the cavity. To minimize tool wear, ideally take the tool radius and increase it by 130% to get the corner radius.

Using this guideline typically avoids a tool change between the end mill used to cut the pocket and the end mill needed to achieve the internal corner.

Using a corner radius that is larger than the end mill radius allows the end mill to avoid a sharp 90-degree toolpath, resulting in better surface finish.

Vertical Internal Corner Radius Deeper Dive

Internal edges, particularly the vertical corner radius, are crucial in CNC machining. The recommended value for this is at least one-third of the cavity depth. Adhering to this guideline ensures that the right diameter tool is used, which aligns perfectly with the cavity depth guidelines.

But there's more to it than just following guidelines. By slightly increasing the corner radii (even by as little as 1 mm), the tool can follow a rounded path rather than a sharp 90-degree angle. This subtle change can significantly enhance the surface finish, giving the product a polished look. If your design demands sharp 90-degree internal corners, integrating a T-bone undercut is a savvy move.

But there's more to it than just following guidelines. By slightly increasing the corner radii (even by as little as 1 mm), the tool can follow a rounded path rather than a sharp 90-degree angle. This subtle change can significantly enhance the surface finish, giving the product a polished look. If your design demands sharp 90-degree internal corners, integrating a T-bone undercut is a savvy move.

Floor Edge Radius

Floor Edge Radius Guidelines

Recommended: If possible, stick to .5mm, 1mm, or no radius.

Using this guideline typically avoids a tool change between the end mill used to cut the pocket and the end mill needed to achieve the floor edge radius.

Most machinists are used to dealing in common floor radius values, so if possible stick to those.

Floor Edge Radius Deeper Dive

The floor radius is another critical aspect of CNC design. While end mill tools typically have a flat or slightly rounded bottom edge, other radii can be achieved using ball end tools. For best results, it's recommended to stick to a floor radius of 0.5 mm, 1 mm, or even no radius at all. This isn't just a random suggestion; it's a preference rooted in the experience of seasoned machinists.

Thin Wall Considerations

Thin Wall Guidelines

Recommended wall thickness minimums: Plastics: 1.5 mm, Metals: .8 mm

Thin walls are weak and likely to vibrate during machining, reducing accuracy.

Secondary effects of thin walls, such as heat-induced deformations in plastic, can result during or after machining in some materials.

Thin Wall Deeper Dive

Thin walls can be tricky. The thinner the wall, the less rigid the material becomes. This lack of rigidity can lead to increased vibrations during machining, potentially compromising accuracy. This is especially true for plastics, which are susceptible to warping due to residual stresses and softening from temperature fluctuations. As a guideline, a minimum wall thickness of 0.8 mm for metals and 1.5 mm for plastics is recommended. However, always assess these values based on the specific project and material in use.

Machining Holes

Hole Guidelines

Recommended sizes: Where possible, stick to standard hole sizes so the machinist can use drill bits. Hole depth is ideally between 4-10x the drill bit diameter, but up to 40x the diameter can be achieved in some cases.

Most common hole sizes have standard bits, so using common holes means much cheaper machining costs.

Non-standard hole sizes will require end mills instead of drill bits. For these types of holes, the cavity depth guidelines will apply.

Hole Deeper Dive

Holes, whether for aesthetic or functional purposes, are a common feature in CNC machined parts. These are typically crafted using drill bits or end mills. The drill bit sizes are standardized, making it easier to achieve consistent results. For holes demanding tight tolerances, reamers and boring tools come into play. For precision holes under 20 mm in diameter, sticking to standard sizes is the best approach.

When it comes to depth, the guidelines are clear. For non-standard hole diameters, end mills are the tool of choice. Here, the maximum cavity depth guidelines come into play. Deeper holes require specialized drills, and it's essential to note the difference in the hole's base depending on the tool used.

When it comes to depth, the guidelines are clear. For non-standard hole diameters, end mills are the tool of choice. Here, the maximum cavity depth guidelines come into play. Deeper holes require specialized drills, and it's essential to note the difference in the hole's base depending on the tool used.

Machining Threads

Thread Machining Guidelines

Recommended thread sizes: M1 at the lower end, but M6 or larger recommended.

Recommended thread lengths: 1.5x nominal diameter on the lower end, but 3x nominal diameter recommended.

Thread Machining Deeper Dive

Threads, both internal and external, are integral to many CNC machined parts. While taps handle internal threads and dies manage external ones, CNC threading tools are becoming increasingly popular. They're preferred by many machinists because they minimize the risk of tap breakage.

In terms of length, the first few teeth of a thread bear the brunt of the load. Hence, threads longer than three times the nominal diameter might be overdoing it and are often unnecessary.

For threads in blind holes made using taps (specifically those under M6 in size), ensure there's an unthreaded section at the hole's base, equivalent to 1.5 times the standard diameter. However, when utilizing CNC threading tools for threads exceeding M6, the entire depth of the hole can be threaded.

In terms of length, the first few teeth of a thread bear the brunt of the load. Hence, threads longer than three times the nominal diameter might be overdoing it and are often unnecessary.

For threads in blind holes made using taps (specifically those under M6 in size), ensure there's an unthreaded section at the hole's base, equivalent to 1.5 times the standard diameter. However, when utilizing CNC threading tools for threads exceeding M6, the entire depth of the hole can be threaded.

Very Small Holes

Small Hole Guidelines

Keep minimum hole diameter to .1" / 2.5 mm for most machine shops.

Specialty shops can often achieve holes down to .005" / .05 mm.

In the world of CNC, size matters. Most workshops are equipped to handle tools down to 2.5 mm in diameter. Anything smaller enters the realm of micro-machining, which demands unique tools and a deep understanding of the cutting process at this scale.

Tolerances in CNC: Striking the Balance

Tolerance Guidelines

Most common tolerances are between ±0.005” and ±0.030” / ±.127 mm and 0.762 mm

Lower tolerances can be achieved but are more expensive.

Tolerance Deeper Dive

Tolerances are the acceptable limits within which a dimension can vary. These are crucial in ensuring the final product meets the desired specifications. Depending on the part's geometry and base dimension, the achievable tolerances can vary. As a general guideline, a tolerance of ±0.1 mm is typical, but with precision tools and expertise, a tolerance of ±0.02 mm is feasible. If you're machining parts yourself with CAM software, you'll see firsthand how very tight tolerances can increase cycle time.

Text and Lettering in CNC Design

Text and Lettering Guidelines

Recommended minimum size: font-size 20 / 5mm / .2"

Recommended geometry: engrave when you can - embossing requires more machining

Choose sans-serif fonts like Arial or Verdana - most machine shops are good at those.

Text and lettering deeper dive

Incorporating text or lettering into a CNC design adds a touch of personalization. Engraved text, which removes less material than embossed text, is the preferred method. For best results, a minimum font size of 20 in sans-serif fonts like Arial or Verdana is recommended, given that many CNC machines are optimized for these fonts.